g

eneral

InFormatIon

1.1 I

dentIFIcatIon

data

oF

tHe

manuFacturer

and

tHe

compressor

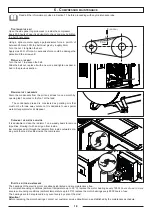

COMPRESSOR

IDENTIFICATION

NAMEPLATE (Example)

I

nFormatIon

on

macHIne

tecHnIcal

/

maIntenance

servIce

We remind you that our technical service department is at your complete disposal to help you resolve any problems that may possibly

be encountered, or to provide you with any other information necessary.

In the case of need contact Our CUSTOMER TECHNICAL SERVICE department or your local dealer.

The constant and efficient performance of the compressor is ensured only if original spare parts are used.

We recommend therefore that you strictly observe the indications provided in the MAINTENANCE section and to use EXCLUSIVELY

original spare parts.

The use of NON ORIGINAL spare parts automatically annuls the guarantee.

g

eneral

saFety

warnIngs

IMPORTANT INSTRUCTIONS FOR THE SAFE USE OF THE COMPRESSOR

THE INAPPROPRIATE USE AND POOR MAINTENANCE OF THIS COMPRESSOR MAY CAUSE PHYSICAL INJURY TO

THE USER. YOU ARE RECOMMENDED TO CAREFULLY FOLLOW THE INSTRUCTIONS PROVIDED HEREAFTER

TO AVOID SUCH RISKS.

1. DO NOT TOUCH MOVING PARTS

Never put your hands, fingers or other parts of the body near moving parts of the compressor.

2. NEVER USE THE COMPRESSOR WITHOUT THE SAFETY GUARDS FITTED

Never use the compressor without all the safety guards fitted perfectly in their correct place (i.e. panelling, belt guard, safety valve).

If these parts are to be removed for maintenance or servicing purposes, ensure that they are put back in their original place perfectly

before using the compressor again.

3. ALWAYS WEAR SAFETY GOGGLES

Always wear goggles or equivalent eye protection means. Never direct compressed air towards any part of your body or that of others.

4. PROTECT YOURSELF AGAINST ELECTRIC SHOCKS

Avoid accidentally touching the metal parts of the compressor with your body, such as pipes, the tank or metal parts connected to

earth. Never use the compressor where there is water or in damp rooms.

5. DISCONNECT THE COMPRESSOR

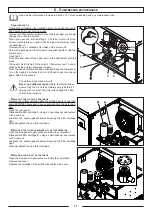

Disconnect the compressor from the electric power supply and completely discharge the pressure from the tank before carrying out

any service, inspection, maintenance, cleaning, replacing or inspection jobs of each part.

6. ACCIDENTAL START-UP

Never move the compressor while it is connected to the electrical power supply or when the tank is pressurised. Ensure that the main

switch is turned OFF before connecting the compressor to the electrical power supply.

7. STORE THE COMPRESSOR APPROPRIATELY

When the compressor is not in use, it must be stored in a dry room away from atmospheric agents. Keep it out of children’s reach.

8. OPERATIONAL AREA

Keep the work area clean and remove any tools that are not required. Keep the work area sufficiently ventilated. Never use the com-

pressor in the presence of flammable liquids or gas. The compressor may produce sparks while running. Do not use the compressor

where there may be paints, gasoline, chemical compounds, glues and any other flammable or explosive material.

9. KEEP THE COMPRESSOR OUT OF CHILDREN’S REACH

Prevent children or anyone else from touching the power supply cable of the compressor. All outsiders must be kept at a safe distance

from the operational area.

10. WORK CLOTHES

Do not wear unsuitable clothing, ties or jewellery as these may get caught up in moving parts. Wear caps to cover your hair if necessary.

11. PRECAUTIONS FOR THE POWER SUPPLY CABLE

Do not disconnect the power supply plug by pulling on the cable. Keep the cable away from heat, oil and sharp edges. Do not stand

on the electrical cable or squash it under heavy weights.

12. LOOK AFTER THE COMPRESSOR WITH CARE

Follow the maintenance instructions. Inspect the power supply cable on a periodic basis and if damaged it must be repaired or re-

4

g

eneral

InFormatIon

Содержание New Silver Series

Страница 20: ...7 Wiring diagram 20 7 Wiring diagram ...

Страница 21: ... 21 7 Wiring diagram ...

Страница 22: ... 22 7 Wiring diagram ...

Страница 23: ... 23 7 Wiring diagram ...

Страница 24: ... 24 7 Wiring diagram ...

Страница 25: ... 25 7 Wiring diagram ...

Страница 26: ... 26 7 Wiring diagram ...

Страница 27: ... 27 7 Wiring diagram ...

Страница 28: ... 28 7 Wiring diagram ...

Страница 29: ... 29 7 Wiring diagram ...

Страница 30: ... 30 7 Wiring diagram ...

Страница 31: ... 31 7 Wiring diagram ...

Страница 32: ... 32 7 Wiring diagram ...

Страница 33: ... 33 7 Wiring diagram ...

Страница 34: ... 34 7 Wiring diagram ...

Страница 35: ... 35 7 Wiring diagram ...

Страница 36: ... 36 7 Wiring diagram ...

Страница 37: ...37 7 Wiring diagram 7 Wiring diagram ...

Страница 38: ...38 7 Wiring diagram ...

Страница 39: ...39 7 Wiring diagram ...

Страница 40: ...40 7 Wiring diagram ...

Страница 41: ...41 7 Wiring diagram ...

Страница 42: ...42 7 Wiring diagram ...

Страница 43: ...43 7 Wiring diagram ...

Страница 44: ...44 7 Wiring diagram ...

Страница 45: ...45 7 Wiring diagram ...

Страница 46: ...46 7 Wiring diagram ...

Страница 47: ...47 7 Wiring diagram ...

Страница 48: ...48 7 Wiring diagram ...

Страница 49: ...49 7 Wiring diagram ...

Страница 50: ...50 7 Wiring diagram ...

Страница 51: ...51 7 Wiring diagram ...

Страница 52: ...52 7 Wiring diagram ...

Страница 53: ...53 7 Wiring diagram ...

Страница 54: ...54 7 Wiring diagram ...

Страница 55: ...55 7 Wiring diagram ...

Страница 56: ...56 7 Wiring diagram ...

Страница 58: ...Model Serial No Date Intervention Working hours Signature 9 Maintence Schedule 58 9 Maintence Schedule ...

Страница 59: ...59 9 Maintence Schedule ...

Страница 60: ...Cod 1127340124_02 2017 ...