Product variant

Code

Meaning

-PL

prepared for common supply manifold, vacuum and

exhaust port with QS push-in fittings inch (-BN-PL)

prepared for common supply manifold, vacuum port

with QS push-in fittings, exhaust port with open silencer

(-B-PO/-C-PO)

Pneumatic ports

-PO

prepared for common supply manifold, vacuum port

with QS push-in fittings inch, exhaust port with open

silencer (-BN-PO)

-ON

N/O, normally open (vacuum generation)

-OE

N/O, normally open (vacuum generation) with ejector

pulse

-OPE

N/O, normally open (vacuum generation) with power

ejector pulse (-C)

-CN

N/C, normally closed (no vacuum generation)

-CE

N/C, normally closed (no vacuum generation) with eject-

or pulse

Normal position of the

vacuum generator

-CPE

N/C, normally closed (no vacuum generation) with

power ejector pulse (-C)

Electrical connection

-N

M12 plug (5-pin)

Vacuum sensor

-

Without vacuum sensor (switching input PNP)

-1P

1 switching output PNP

-1N

1 switching output NPN

Tab. 3 Overview of variants

5.2

Function

5.2.1

Switching functions

The solenoid valve for vacuum generation switches as an N/C or N/O contact,

depending on the version, when pressurised with compressed air.

The switching output is configured as a N/O contact and switches depending on a

threshold value comparator

With air saving function activated the switching mode is set as the threshold value

comparator by switching output A.

Threshold value comparator

NO (N/O contact)

Tab. 4 Settings for switching points SP, hysteresis Hy and functional reserve FR

Switching behaviour

Product feature

Normally open contact (N/O)

-OE/-ON/-OPE

Normally closed contact (N/C)

-CE/-CN/-CPE

Tab. 5 Switching characteristics and product feature

Code

Switching output A

Switching input

-1P

Switching output positive switching pres-

sure sensor output A

Switching input positive switching

-1N

Switching output negative switching

pressure sensor output A

Switching input negative switching

without

vacuum

sensor

-

Switching input positive switching

Tab. 6 Switching output and switching input variants

Determination of switching point

The switching point (SP) is determined from the teach point (TP) and the function

reserve (35%).

SP = TP – 0.35*TP

The hysteresis has a fixed value.

5.2.2

Valve control

Control of the ejector pulse

–

Signal-controlled ejector pulse/power ejector pulse

The ejector pulse is generated via a control signal at the ejector pulse switch-

ing input. The duration of the ejector pulse can be set via the duration of the

control signal at the ejector pulse switching input. The vacuum solenoid valve

or the ejector pulse solenoid valve is controlled as defined by the input sig-

nal.

Destruction of the vacuum sensor due to overpressure (-CPE/-OPE)

The exhaust duct is sealed tightly during the power ejector pulse. This can cause

overpressure at the vacuum port and destroy the vacuum sensor.

•

Use power ejector pulse only in open vacuum systems.

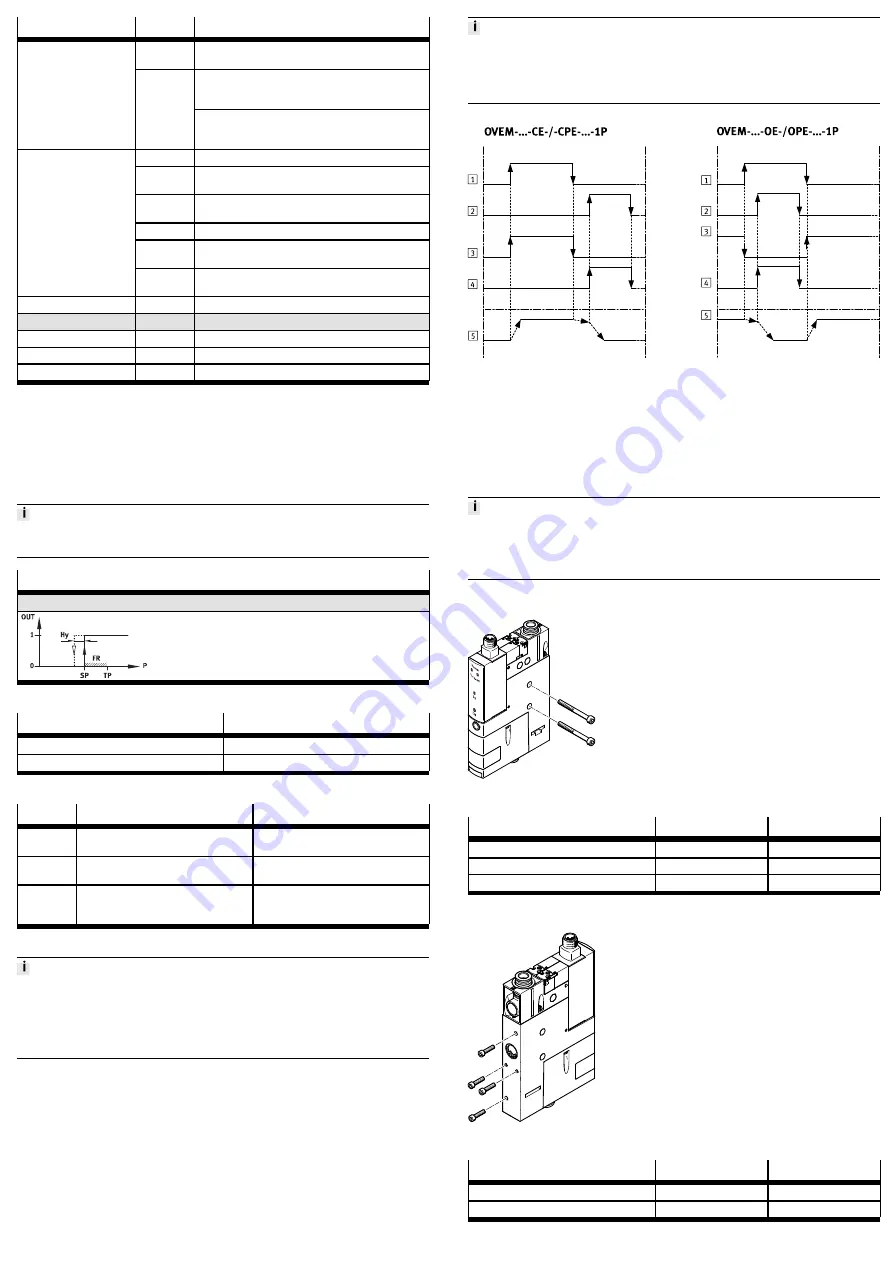

1

Control signal at the vacuum

switching input

2

Control signal at the switching

input ejector pulse / power eject-

or pulse

3

Switching position of vacuum

solenoid valve

4

Switching position of ejector

pulse solenoid valve

5

Vacuum port

Fig. 2 Valve control switching characteristics

6

Assembly

An unfavourable mounting position may impair the function of the product.

•

Avoid condensate accumulation in the device through a suitable mounting

position.

•

Exhaust air must be able to flow out unhindered.

Direct mounting

Fig. 3 Direct mounting on the side

Variant

Screws

Tightening torque

OVEM-...-05/-07/-10-...-B/-BN

M5

max. 2.5 Nm

OVEM-...-14/-20-...-B/-BN

M4

max. 2.5 Nm

OVEM-...-20/-30-...-C

M6

max. 2.5 Nm

Tab. 7 Size and tightening torque of the screws for direct mounting on the side

Fig. 4 Direct mounting on the back

Variant

Screw

Tightening torque

OVEM-...-05/-07/-10/-14/-20-...-B/-BN

M3

max. 0.8 Nm

OVEM-...-20/-30-...-C

M4

max. 0.8 Nm

Tab. 8 Size and tightening torque of the screws with direct mounting on the back