Festo — EXPT-95/120 — 2021-08d

Assembly

13

4.3

Types of mounting

NOTICE

The removal of a motor results in a loss of homing on the corresponding axis. The axis must be homed

again during commissioning.

• Preferably choose mounting holes where the motor does not need to be removed.

4.3.1

Direct fastening

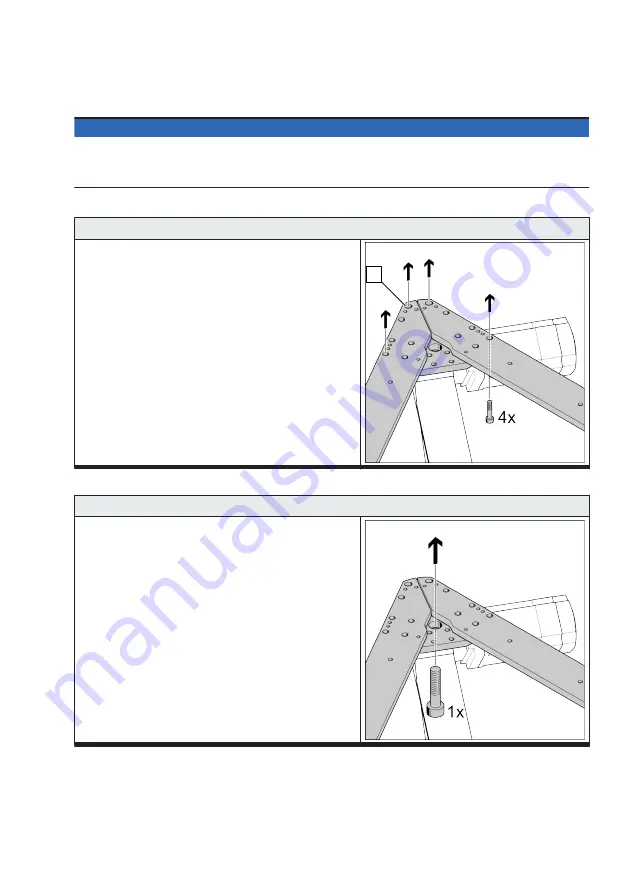

Direct fastening variant 1 with M8 screws in accordance with DIN 912

Direct fastening to the frame with at least 4 screws per

corner bracket.

Dimensions

The 4 screws should be as far apart as possible to

ensure a torsionally rigid connection.

If the slotted holes

1

are used, the bearing surface

of the screws is too small. Use the accompanying

washers.

1

Tab. 7: Direct fastening variant 1

Direct fastening variant 2 with M20 screws in accordance with DIN 912

Direct fastening to the frame with one screw per corner

bracket.

There is a central hole for this purpose at every

bracket.

–

Make sure that the bearing surface lies in the area

of the corner brackets.

Tab. 8: Direct fastening variant 2