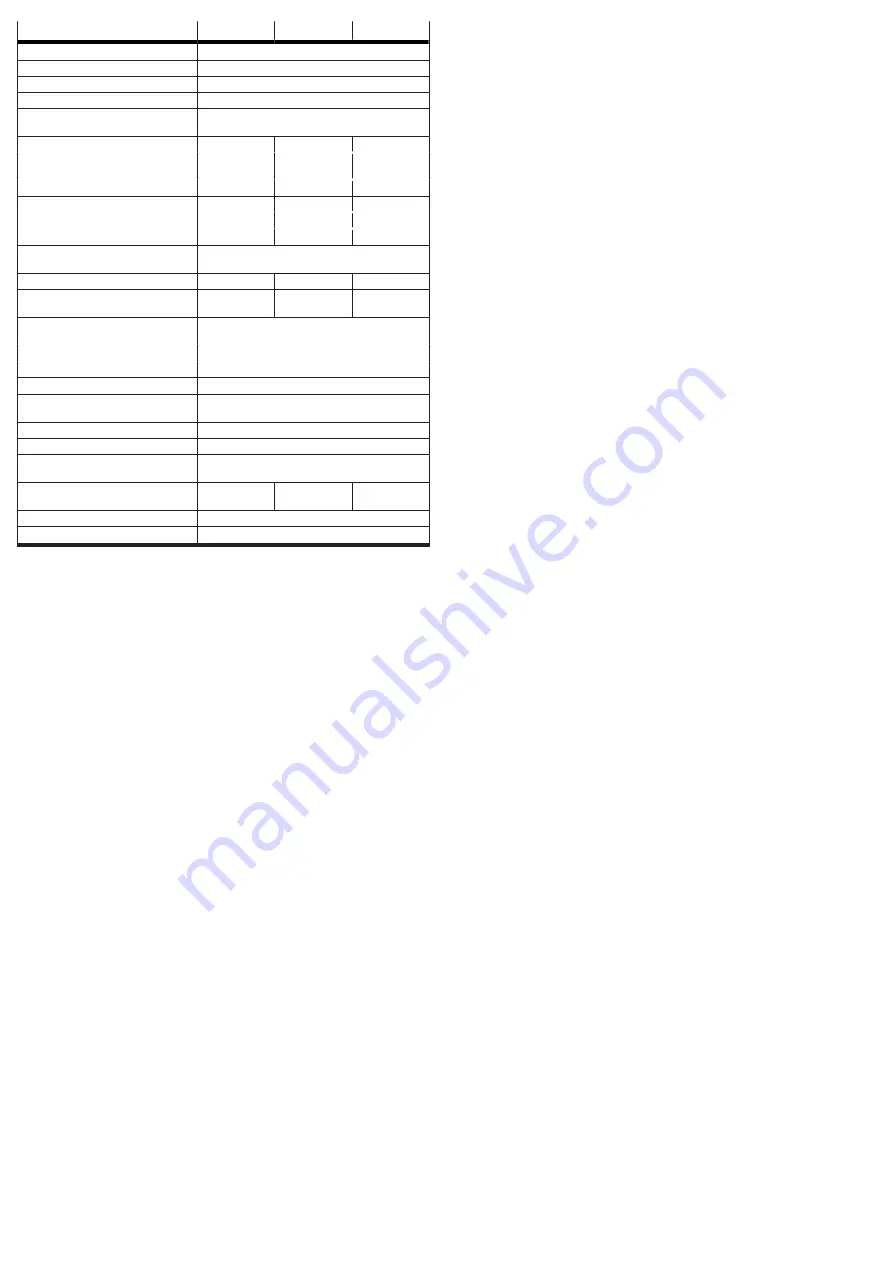

Size

32

45

60

Mounting position

any

Ambient temperature

[°C]

0 … +50

Storage temperature

[°C]

–20 … +60

Degree of protection

IP40

EMCS-ST: Certificates, decla-

ration of conformity

Max. payload

–

horizontal mounting posi-

tion

[kg]

2

6

10

–

vertical mounting position [kg]

2

6

10

Max. velocity

1)

–

with axial kit

[mm/s]

190

250

240

–

with parallel kit

[mm/s]

190

235

205

Velocity "Speed Press/

Speed Ref"

2)

[mm/s]

10

Max. feed force

3)4)

[N]

60

120

250

Max. force on external stops

during homing

5)

[N]

92

190

385

Max. acceleration/decelera-

tion

2)

–

with axial kit

[m/s

2

]

5

–

with parallel kit

[m/s

2

]

3

Duty cycle

[%]

100 (+30 … +50 °C: – 2% per Kelvin)

Distance between stop and

end position

6)

[mm]

1

Repetition accuracy

[mm]

±0.015

Nominal voltage

[V DC]

24

Logic current consumption

(logic, pin 1)

[mA]

DIO operation: 100 ... 300

IO-Link operation: 100 ... 150

Load current consumption

(power, pin 1)

[A]

3

3

5.3

IO-Link port class

A

IO-Link protocol version

Device V 1.1

1) Maximum value for Speed In/Speed Out at level 10

2) Unchangeable parameter.

3) Maximum value for Force at level 10

4) Force is controlled and evaluated by closed-loop control of the motor current. Depending on the mecha-

nism of the drive, a linear force can be calculated from the measured level of current. The target is set as a

percentage of the rated motor current and may deviate from the actual force on the mini slide. At the lower

force levels the frictional force of the drive system may be greater than the set feed force and may result in

the drive system coming to a standstill.

5) The force acts on the stop for

£

100 ms

6) Distance (MechIn – LimIn or MechOut – LimOut)

Tab. 8: Technical data EGSS-BS