DNCKE−...−S / KEC−...−S

Festo DNCKE−...−S / KEC−...−S 1002a English

43

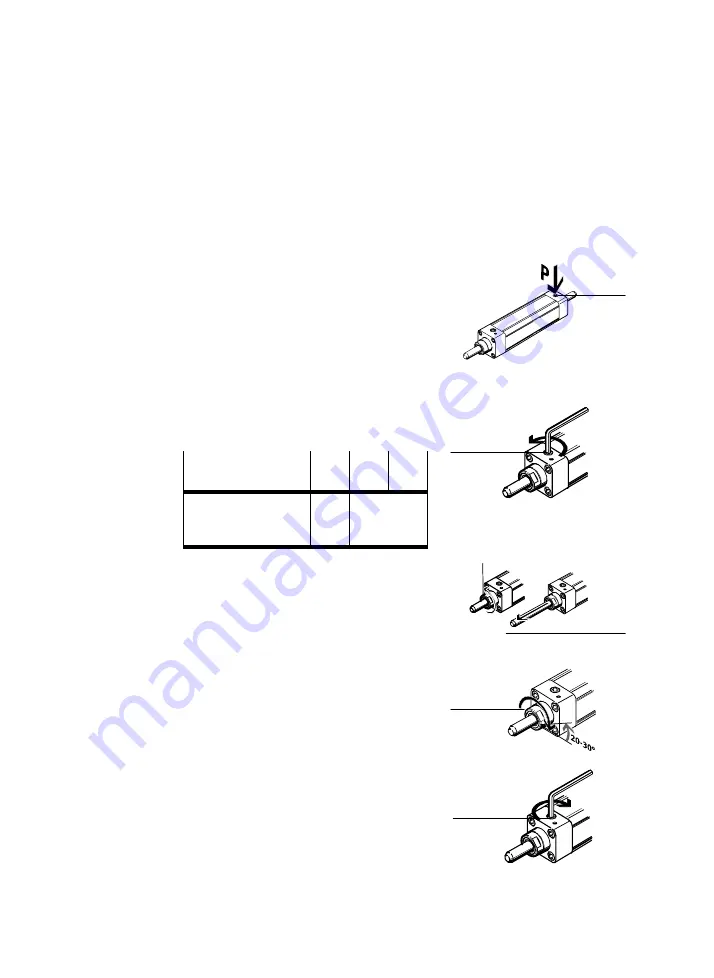

Commissioning preparation (adjustment)

Adjusting the DNCKE−.../KEC−... (adjustment is not required when the DNCKE−.... is

commissioned the first time):

1. Exhaust the cylinder in a stable position

(e.g. if fitted vertically, at the lowest

point).

In this way you will prevent the piston rod

from moving unexpectedly when the

clamping is loosened.

2. Pressurise the supply port

2

with at

least 3.8 bar.

3. Unscrew the locking screw

3

with an

Allen key.

Type

DNCKE−

KEC−

40

16

63

20

100

25

Width across flats for

internal hexagon

socket

SW6

SW8

Fig.23

4. Unscrew the adjusting sleeve

5

half a

turn in an anti−clockwise direction.

5. Now turn the adjusting sleeve

5

:

first clockwise until the clamping rod

can no longer move,

then anti−clockwise until the clamping

rod just moves freely (approx. 20°...30°).

6. Tighten the locking screw

3

again. The

tightening torque is 7 Nm.

7. Vent the clamping unit. The clamping rod

will thereby be clamped.

Fig.21

2

Fig.22

3

Fig.24

5

9

Fig.25

5

Fig.26

3

Содержание DNCKE S Series

Страница 159: ...DNCKE S KEC S Festo DNCKE S KEC S 1002a 159 ...