DNCKE−...−S / KEC−...−S

Festo DNCKE−...−S / KEC−...−S 1002a English

37

S

Use a one−way flow control valve type GRLZ−... or GRLA−... directly at the sup

ply port.

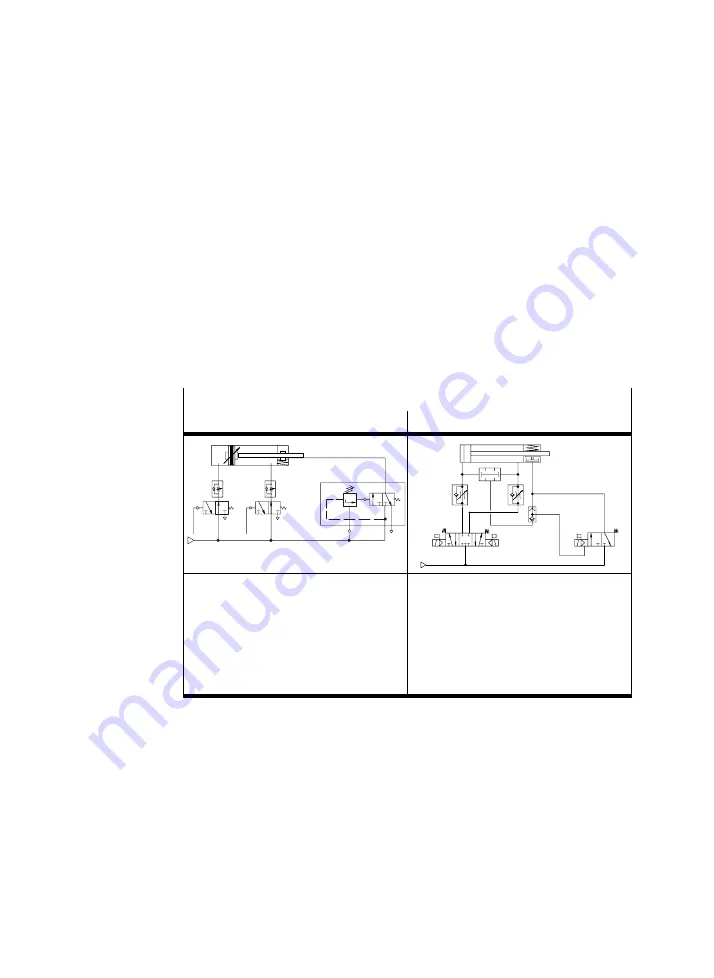

Activating the cylinder with clamping unit:

S

Select the control variant for your application.

The following example controllers meet at most the specified classification to

ISO 13849−1. If a higher performance level (PL) is required (by the result of a

risk analysis or by a corresponding C standard), additional control measures

will have to be taken. To fulfil the requirements for a PL in Cat.2 or higher, addi

tional testing and monitoring measures (DC level) are needed, for example, of

pressure, displacement, valve position.

Example of holding device

Ensuring against pressure failure

Approaching a clamping position

The piston rod is clamped even if there is a

pressure failure.

The controller for the specified safety

function has max. PLc/cat 1 to

ISO 13849−1.

When releasing the clamping unit, there is

movement due to the difference of the pis

ton areas.

The clamping can be loosened if both cyl

inder chambers are pressurised (this is to

avoid a jerky movement when the piston

rod extends).

The controller for the specified safety

function has max. PLd/cat 3 to

ISO 13849−1.

Fig.9

Содержание DNCKE S Series

Страница 159: ...DNCKE S KEC S Festo DNCKE S KEC S 1002a 159 ...