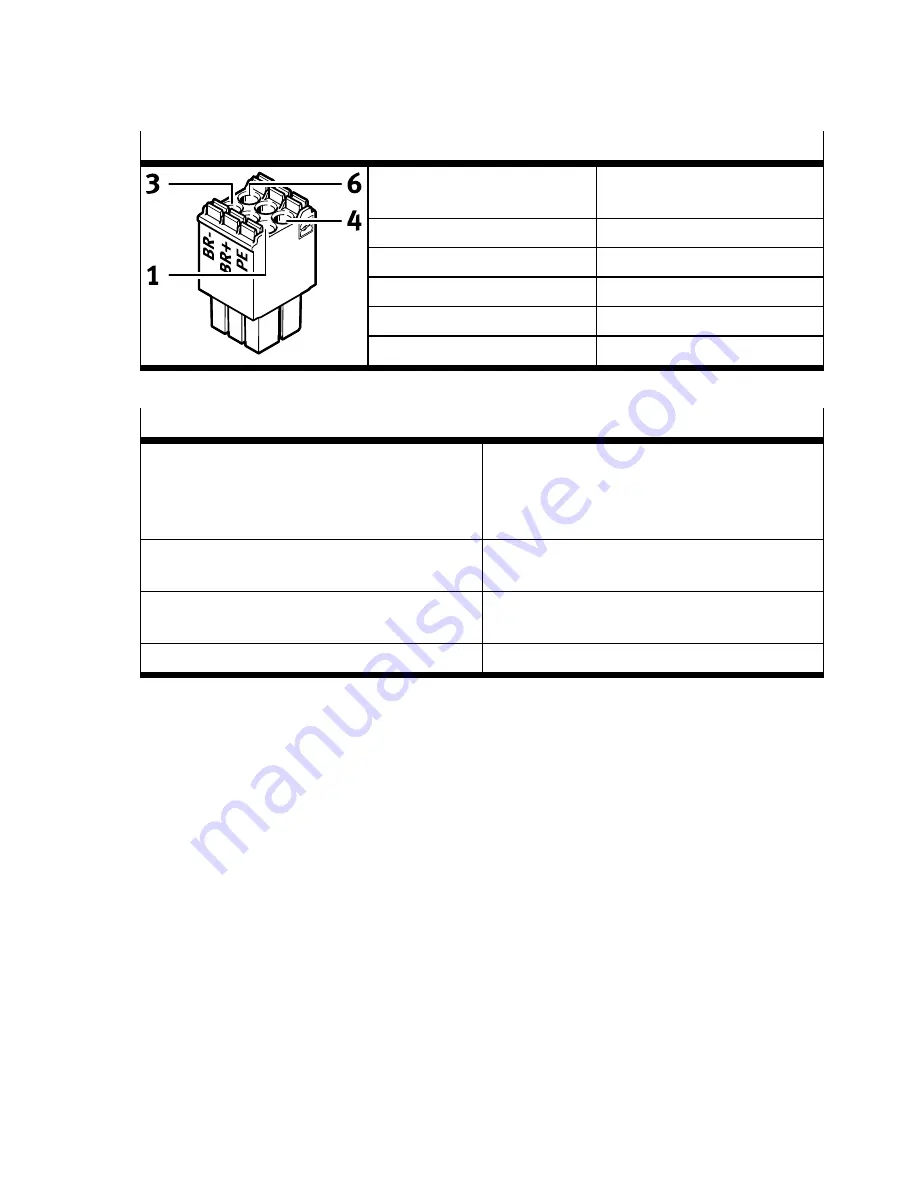

Requirements for the counterplug

Design

DFMC 1.5/ 3-ST-3.5 from

Phoenix Contact or compatible

Signal contacts

6 (3-pin, 2-row)

Nominal current

8 A

Rated voltage (III/2)

160 V

Grid dimension

3.5 mm

Strip length

10 mm

Tab. 60 Requirements for the counterplug

Requirements for the connecting cable

Design

–

2 wires for the line to the holding brake, twis-

ted in pairs, separately shielded

–

2 wires for the line to the temperature

sensor, twisted in pairs, separately shielded

Min. conductor cross section including cable end

sleeve with plastic sleeve

0.25 mm

2

Max. conductor cross section including cable end

sleeve with plastic sleeve

0.75 mm

2

Max. length

50 m

Tab. 61 Requirements for the connecting cable

Requirement for the temperature sensor in the motor

–

Electrically safe separation from the motor phases in accordance with IEC 61800-5-1, voltage

class C, overvoltage category III.

Requirements for the shield support

–

Make unshielded cable ends as short as possible (max. 150 mm).

–

Put in place both sides of the cable shield.

8.9.3

Shield support of the motor cable

Requirements for the device-side shield support of the motor cable

The type of shield support depends on the design of the motor cable. If, for example, a hybrid cable is

used to connect the motor, holding brake, and temperature sensor, the following options exist for pla-

cing the shield on the device side:

Option 1: All motor cable shields are connected over a large surface with a shield sleeve at the cable

end and placed below the shield clamp on the front side of the CMMT-AS.

Installation

63

Festo — CMMT-AS-C2/C4-3A-... — 2018-02