Contents and general safety instructions

XII

Festo P.BE-CDVI-EN en 1202e

Term / abbreviation

Meaning

Separator plate

Sealing variant with open or closed supply ducts. The variants with

closed supply ducts serve to form pressure zones.

Tubing connection

Connecting the supply lines (tubing) to the CDVI.

Tab. 0/1: Index of terms and abbreviations

Содержание CDVI-DN

Страница 2: ......

Страница 4: ...Contents and general safety instructions II Festo P BE CDVI EN en 1202e...

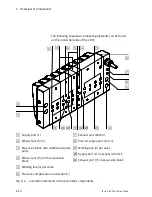

Страница 15: ...Overview of components 1 1 Festo P BE CDVI EN en 1202e Chapter 1 Overview of components...

Страница 31: ...Assembly 2 1 Festo P BE CDVI EN en 1202e Chapter 2 Assembly...

Страница 39: ...Installation 3 1 Festo P BE CDVI EN en 1202e Chapter 3 Installation...

Страница 63: ...Commissioning 4 1 Festo P BE CDVI EN en 1202e Chapter 4 Commissioning...

Страница 100: ...5 Cleaning maintenance and conversion 5 26 Festo P BE CDVI EN en 1202e...

Страница 101: ...Technical appendix A 1 Festo P BE CDVI EN en 1202e Appendix A Technical appendix...

Страница 109: ...A Technical appendix A 9 Festo P BE CDVI EN en 1202e A 2 Accessories www festo com catalogue...

Страница 114: ...A Technical appendix A 14 Festo P BE CDVI EN en 1202e...

Страница 115: ...Index B 1 Festo P BE CDVI EN en 1202e Appendix B Index...

Страница 116: ...B Index B 2 Festo P BE CDVI EN en 1202e Contents B Index B 1...

Страница 122: ...B Index B 8 Festo P BE CDVI EN en 1202e...