Disposal

Observe the local regulations for environmentally appropriate disposal of elec-

tronic modules. The safety module is RoHS-compliant.

The material used in the packaging has been specifically chosen for its recyclabil-

ity.

12

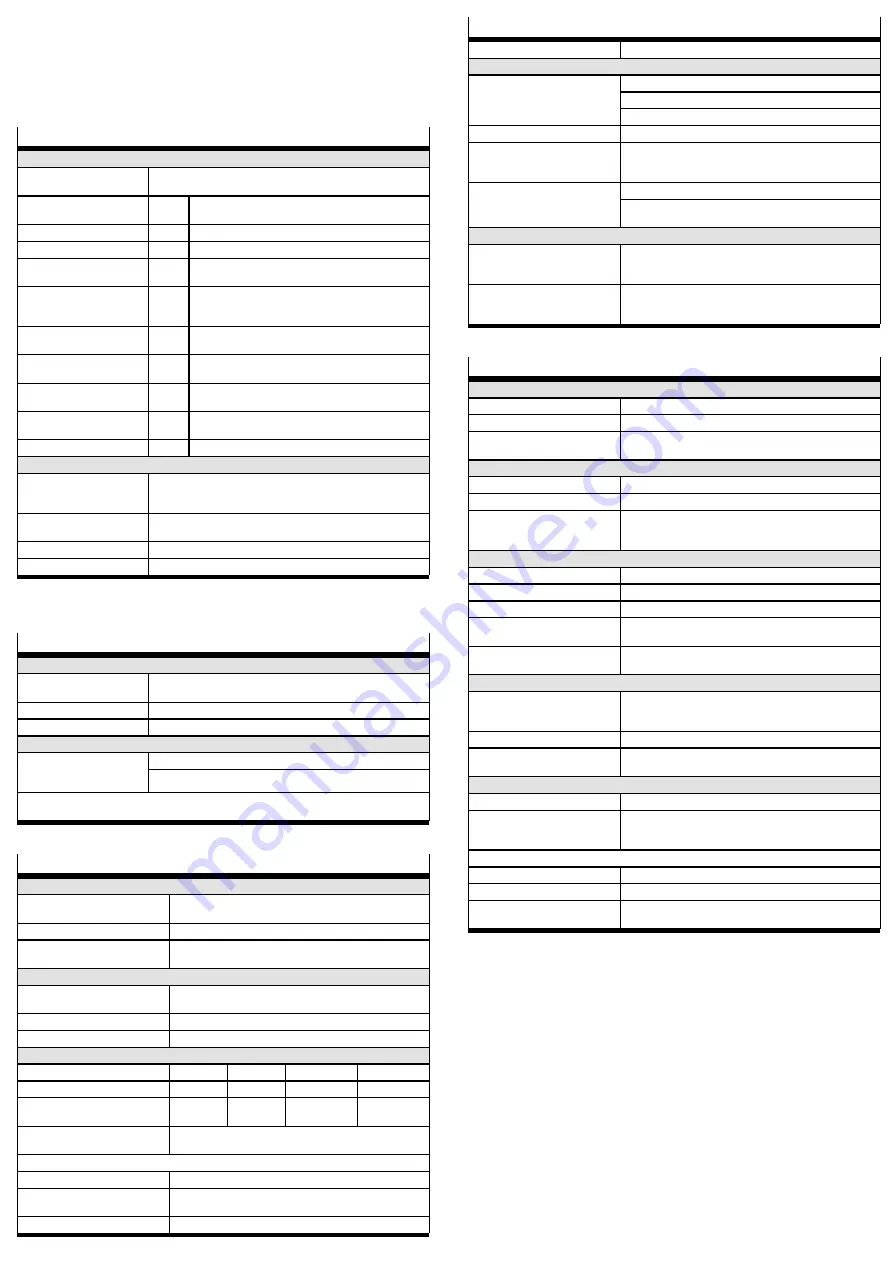

Technical data

Safety engineering

Safety reference data

Safety functions

STO, SS1, SS2, SOS, SLS, SSR, SSM, SBC in accordance with

EN 61800-5-2

SIL

SIL 3

1)

Safety integrity level in accordance with EN 61800-5-2,

EN 61508 and EN 62061

Category

4

1)

Category in accordance with EN ISO 13849-1

Performance level

PL e

1)

Performance level in accordance with EN ISO 13849-1

MTTF

d

[years]

8700

Mean time to dangerous failure in accordance with

EN ISO 13849-1

PFH

[h

-1

]

9.5 x

10

–9

Probability of a dangerous random hardware failure per

hour in accordance with EN 61800-5-2, EN ISO 13849-1,

EN 62061 and EN 61508

DC

[%]

97.5

Diagnostic coverage in accordance with EN 61800-5-2,

EN 61508 and EN ISO 13849-1 and EN 62061

HFT

1

Hardware fault tolerance in accordance with

EN 61800-5-2, EN 62061 and EN 61508

SFF

[%]

99.5

Safe failure fraction in accordance with EN 61800-5-2,

EN 62061 and EN 61508

T

[years]

20

Proof test interval in accordance with EN 61800-5-2,

EN 61508 and EN 62061

T

M

[years]

20

Service life in accordance with EN ISO 13849-1

Safety specifications

Type test

The functional safety engineering of the product was certified by an

independent testing authority in accordance with section 2.4; see

EC-type examination certificate

è

Certificate issuing authority

TÜV Rheinland (German Technical Control Board), Certification

Body of Machinery, NB 0035

Certificate no.

01/205/5165.02/19

Well-tried component

Yes

1) Maximum achievable classification, limitations dependent on the safety function as well as the circuitry

and the encoders.

Tab. 6

General

Mechanical

Dimensions (L x

W x H)

[mm]

112.2 x 99.1 x 28.7

Weight

[g]

Approx. 220

Note on materials

RoHS-compliant

Approvals (safety module CAMC-G-S3 for motor controller CMMP-AS-…-M3)

In accordance with EU EMC Directive

CE marking (see declaration of

conformity)

è

In accordance with EU Machinery Directive

The device is intended for use in an industrial environment. Measures for interference suppression

may be required in residential areas.

Tab. 7

Operating and environmental conditions

Transport

Permissible temperat-

ure range

[°C]

–25 … +70

Humidity

[%]

0 … 95, at max. 40 °C ambient temperature

Maximum transporta-

tion duration

[weeks]

Maximum 4 in the total product lifecycle

Storage

Permissible temperat-

ure range

[°C]

–25 … +55

Humidity

[%]

5 … 95, non-condensing/protected against condensation

Permissible altitude

[m]

<

3000 (above sea level)

Ambient conditions CMMP-AS-...-M3 with safety module CAMC-G-S3 in Ext3

CMMP-AS-...

C2-3A-M3

C5-3A-M3

C5-11A-P3-M3

C10-11A-P3-M3

Ambient temperature

[°C]

0 … +35

0 … +40

0 … +40

0 … +40

Ambient temperature

with power reduction

[°C]

+35 … +40

+40 … +50

+40 … +50

+40 … +45

Humidity

[%]

0 … 90 (non-condensing). No corrosive media permitted in the

environment of the device.

Permissible setup altitude above sea level

–

At nominal power [m]

1000

–

With power

reduction

[m]

1000 … 2000

Degree of protection

IP20 (mounted in CMMP-AS-...-M3).

Operating and environmental conditions

Vibration/shock

Requirements of EN 61800-5-1 and EN 61800-2 are fulfilled.

Electrical operating conditions

Control voltage of the basic unit

24 V control voltage (all inputs and outputs)

Galvanically isolated

potential areas

Potential-free signal contact C1/C2

System voltage

[V]

<

50 (24 V PELV power supply in accordance with EN 60204-1)

Overvoltage category

in accordance with

EN 61800-5-1

3

2

Pollution degree in

accordance with

EN 61800-5-1

This must always be guaranteed with appropriate measures,

e.g. by installation in a control cabinet.

EMC operating conditions

Immunity to interfer-

ence

Requirements for “second environment” in accordance with

EN 61800-3 (PDS of category C3)

Requirements in accordance with EN 61326-3-1

Interference emission

Requirements for “first environment with restricted

availability” in accordance with EN 61800-3 (PDS of category

C2)

Tab. 8

Electrical data

Digital inputs DIN40A/B to DIN43A/B and DIN44 to DIN49

Input

Type 3 in accordance with IEC 61131-2

Nominal voltage

[V DC]

24

Permissible voltage

range

[V]

–3 … 30

Digital outputs DOUT40A/B to DIN42A/B

Output

High-side switch with pull-down

Voltage range

[V DC]

18 … 30

Permissible output

current

I

L,nominal

[mA]

<

50

Signal contact C1/C2

Design

Relay contact, N/O contact

Voltage range

[V DC]

18 … 0

Output current I

L,nominal

[mA]

<

200

Short circuit/overcur-

rent protection

Not short-circuit-proof, overvoltage-proof up to 60 V

Service life of feed-

back contact

[n

op

]

10 x 10

6

(at 24 V and I

Contact

= 10 mA, the service life is

reduced with higher load currents)

24V auxiliary power supply

Design

Logic supply voltage routed over the motor controller (fed in at

[X9], not additionally filtered or stabilised). Protected against

reverse polarity, overvoltage-proof up to 60 V DC

Nominal voltage

[V]

24

Output current I

L,nominal

(nominal)

[mA]

100

Cabling [X40]

Max. cable length

[m]

<

30

Shielding

Use shielded cable for wiring outside the control cabinet.

Guide shielding into the control cabinet/attach to the side of

the control cabinet

Conductor cross section (flexible conductors, wire end sleeve with insulating collar)

–

One conductor

[mm

2

]

0.25 … 0.5

–

Two conductors

[mm

2

]

2 x 0.25 (with twin wire end sleeves)

Tightening torque of

mating plug

[Nm]

0.22 … 0.25

Tab. 9