6

GENERAL SPECIFICATIONS

ENGLISH

ENGLISH

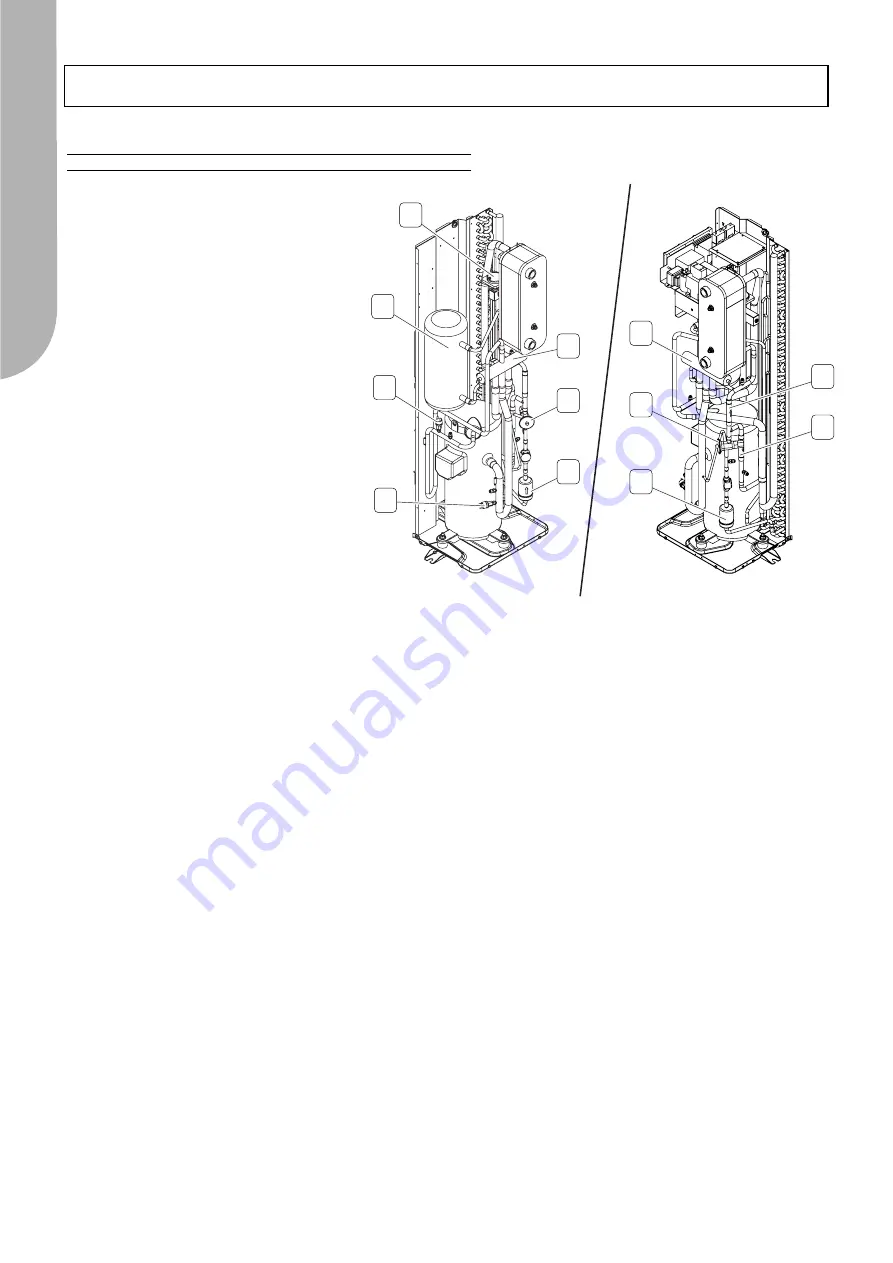

Hydraulic and chilling circuit components (Fig.2):

1. One-way valves (only IP units

), make the

refrigerant obligatorily pass through the appro-

priate heat exchangers, depending on the

operating cycle.

2. Low pressure switch

, with fixed setting. It is

installed on the suction pipe and blocks the

compressor if the operating pressures drop

below the tolerated values. It automatically

resets as the pressure increases. If it activates

frequently, the unit will block and can only be

restarted by resetting via the user interface

terminal.

3. High pressure switch

, with fixed setting. It is

installed on the delivery pipe and blocks the

compressor if the operating pressures exceed

the tolerated values. If it activates, the unit will

block and can only be restarted by resetting

via the user interface terminal.

4. Thermostatic valve

, of the type with external

equalizer.

Used as both a heat pump and chiller, it’s task

is to supply the evaporator correctly, keeping

the selected degree of superheat at a steady

level.

5. Dehydrator filter

of the mechanical type. Retains impurities and traces of moisture in the circuit.

6. Differential water pressure switch

. This is standard supply and is installed on the connections between the exchanger’s

water inlet and outlet. If it activates frequently, the unit will block and can only be restarted by resetting via the user interface

terminal.

7. 4-way cycle reversing valve

(

IP units only).

Reverses the direction in which the refrigerant flows when the summer/winter

operating modes change.

8. Fluid receiver

(

IP units only).

This is a plenum tank that accounts for the refrigerant charge variations required by the machi-

ne as the summer/winter operating modes change.

6

3

7

4

5

4

1

1

7

5

2

8

Fig.2