24

Ferroli F 24 B

3. SERVICE AND MAINTENANCE

3.1 Adjustments

All adjustment and conversion operations must be carried out by Qualified Personnel such as

the Ferroli Technical Service.

FERROLI declines any responsibility for damage or physical injury caused by unqualified and unauthorized

persons tampering with the device.

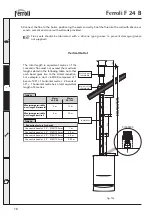

Adjusting the pressure and fl ow rate to the main burner

This boiler operates on the flame modulation principle. It has two fixed pressure values, minimum and

maximum, which must be as shown in the table 10, whichever type of gas is used.

Note - Because correct minimum and maximum pressures are critical to the efficient operation

of the boiler it is ESSENTIAL that the following adjustments are carried out by COMPETENT

personnel ONLY.

Adjusting minimum and maximum pressure Honeywell V K4105G gas valve

- Connect suitable pressure gauge to burner test point “B” downstream of the gas valve.

- Disconnect the pressure compensation tube «F».

- Remove the protective cap «C».

- Adjust potentiometre P3 (on the main board) at

minimum (clockwise).

- Operate boiler for central heating

- Adjust minimum pressure by rotating screw «D»

clockwise toreduce pressure and anticlockwise

to increase pressure.

- Adjust potentiometre P3 at maximum (anti-

clockwise)

- Adjust max pressure by rotating screw «E»,

clockwise to increase pressure and anticlockwise

to reduce pressure.

- Reconnect the pressure compensation tube

«F».

- Replace protective cap «C».

IN

OUT

C

F

E

B

A

D

Key

A =

Gas inlet test point

B =

Gas outlet test point

C =

Protection cup

D =

Min. pressure adjusting screw

E =

Max. pressure adjusting screw

F =

Balancing tube

Fig. 15