DIVAPROJECT F24

27

EN

cod. 3541F161 - Rev. 00 - 05/2014

4. SERVICE AND MAINTENANCE

All adjustment, conversion, commissioning and maintenance operations described be-

low must only be carried out by Qualified Personnel (meeting the professional technical

requirements prescribed by current regulations) such as those of the Local After-Sales

Technical Service.

FERROLI declines any liability for damage and/or injury caused by unqualified and un-

authorised persons tampering with the unit.

4.1 Adjustments

Gas conversion

The unit can work on natural gas or LPG and is factory-set for use with one of these two

gases, as clearly shown on the packing and data plate. Whenever a different gas to that

for which the unit is arranged has to be used, the special conversion kit will be required,

proceeding as follows:

1.

Disconnect the boiler power supply and close the gas cock.

2.

Replace the nozzles at the main burner, fitting the nozzles specified in the technical

data table in sec. 5.4, according to the type of gas used.

3.

Supplying power to the unit and open the gas cock.

4.

Change the parameter for the type of gas:

•

put the boiler in stand-by mode

•

press the RESET button for 10 seconds: leds flashing fast for two seconds

•

red LED ON

•

press the RESET button for 5 seconds: leds flashing fast for two seconds

•

turn the DHW knob (rif. 2 - fig. 1) to minimum (for Natural Gas operation) or onto

maximum (for LPG operation)

•

press the RESET button for 5 seconds: leds flashing fast for two seconds

•

Green LED ON

•

turn the heating knob (rif. 1 - fig. 1) to a minimum and then a maximum

•

the boiler will return to stand-by mode

•

place the knobs onto the set temperatures

5.

Adjust the minimum and maximum pressures at the burner (see relevant section),

setting the values given in the technical data table for the type of gas used

6.

Apply the sticker, contained in the conversion kit, near the data plate as proof of the

conversion.

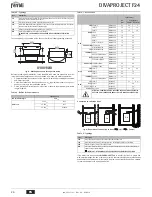

TEST mode activation

Press the

RESET button 3 times within 3 seconds

to activate

TEST mode

. The boiler

lights at the maximum heating power set as described in the following section.

If

TEST mode is activated

and enough hot water is drawn to activate DHW mode, the

boiler will stay in

TEST mode

but the 3-way valve switches to DHW.

Press the

RESET button 3 times within 3 seconds

to exit

TEST mode

. On exiting

TEST mode

, the set maximum heating power will not be modified.

The TEST mode is automatically disabled in any case after 15 minutes or on stopping of

hot water drawing (if enough hot water is drawn to activate DHW mode).

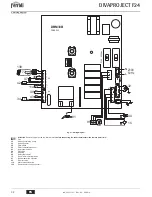

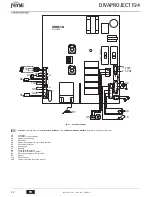

fig. 10 - TEST mode

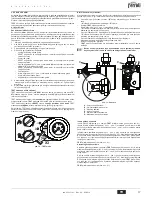

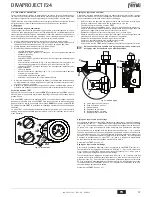

Adjustment of pressure at the burner

Since this unit has flame modulation, there are two fixed pressure values: the minimum

and maximum, which must be those given in the technical data table according to the

type of gas.

•

Connect a suitable pressure gauge to pressure point

“B”

located downstream of the

gas valve

•

Remove the protection cap

“D”

undoing screw

“A”

.

•

Operate the boiler in

TEST mode

.

•

Turn the heating knob (ref. 1 - fig. 1) to max.

•

Adjust the max. pressure with screw

"G"

, clockwise to increase the pressure and

anticlockwise to decrease it

•

Disconnect one of the two Faston connectors from the modureg

"C"

on the gas valve.

•

Adjust the min. pressure with screw

"E"

, clockwise to decrease the pressure and

anticlockwise to increase it.

•

Reconnect the Faston connector detached from the modureg on the gas valve.

•

Check that the maximum pressure has not changed.

•

Refit protection cap

“D”

.

•

To end the

TEST mode

repeat the activation sequence or wait 15 minutes.

A

After checking or adjusting the pressure, make sure to seal the adjust-

ment screw with paint or a specific seal.

fig. 11 - Gas valve

A

- Protection cap screw

B

- Pressure point downstream

C

- Modureg cable

D

- Protection cap

E

- Min. pressure adjustment

G

- Max. pressure adjustment

Heating power adjustment

To adjust the heating power, switch the boiler to

TEST mode

(see sec. 4.1). Turn the

heating temperature control knob (ref. 1 - fig. 1) to minimum: the LEDs start flashing se-

quentially, yellow - green - red, indicating the heating power adjustment phase.

Turn the heating temperature control knob (ref. 1 - fig. 1) clockwise to increase the power

or anticlockwise to decrease it (see sec. 5.5). On reaching the desired power, press the

ECO button and the maximum power will remain that just set; the LEDs return to diag-

nose the TEST mode (see sec. 4.1) indicating memorisation of the maximum heating

power just set.

Exit

TEST mode

(see sec. 4.1).

Lighting power adjustment

To adjust the lighting power, switch the boiler to

TEST mode

(see sec. 4.1). Turn the

DHW temperature control knob (ref. 2 - fig. 1) to minimum: the LEDs start flashing se-

quentially, yellow - green - red, indicating the lighting power adjustment phase.

Turn the DHW temperature control knob (ref. 2 - fig. 1) clockwise to increase the power

or anticlockwise to decrease it (see sec. 5.5). On reaching the desired power, press the

ECO button and the lighting power will remain that just set; the LEDs return to diagnose

the

TEST mode

(see sec. 4.1) indicating memorisation of the lighting power just set.

Exit

TEST mode

(see sec. 4.1).

X3

C

D

B

A

D

C

E

G

Содержание DIVAPROJECT F24

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it ...