48

EN

USE

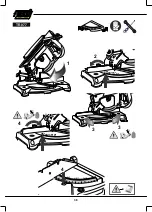

PERMITTED USE -

This machine has been designed and manufactured for cutting operations in mitre

saw or bench saw mode.

Bench saw mode:

seasoned wood

Mitre saw mode

: seasoned wood, plastic materials, aluminium and its alloys

UNINTENDED USE -

IT is forbidden to:

• operate on ferrous materials.

• operate on organic materials and/or food stuff s.

• operate on materials which may release toxic substances during the cutting process.

• cut damp wood when using the machine in bench saw mode.

• use the machine when the safety guards are not in position.

• use high-speed steel blades.

• use the machine to make blind cuts.

• cut metal material when using the machine in circular saw mode.

This machine is not suitable for use in potentially explosive environments.

RESIDUAL RISKS

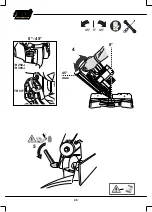

Shearing, cutting and severing hazard -

Risk indicated by this symbol:

Entanglement, drawing-in and entrapment hazard:

This risk is indicated by this symbol:

Precautions to be taken

• During the cutting phase do not wear work gloves.

• Keep hands away from the work area.

• Never remove cuttings or fragments from the machine when the blade is rotating.

Crushing hazard:

This risk is indicated by this symbol:

Precautions to be taken

• Keep hands away from the head rotation area.

• Keep your face away from the cutting area;

• Never bring hands anywhere near the cutting zone until the head has returned to its full height

and the blade has come to a complete standstill;

• To avoid breaking the blade, reduce pressure as soon as the blade comes into contact with

the workpiece;

• Lessen the cutting pressure to safeguard the machine.

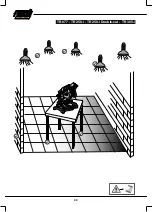

INFORMATION CONCERNING NOISE -

The noise values indicated are emission levels and not

necessarily safe operating levels. While there is a correlation between emission levels and exposure

levels, this cannot reliably be used to determine whether or not further safety precautions are needed.

Factors which infl uence the real level of a worker's exposure include the duration of exposure, the

characteristics of the working environment, other sources of noise, for example the number of machines

or operations being carried out in the near vicinity. Furthermore, levels of safe exposure may be fi xed

diff erently from one country to another. This information does however help the machine user to better

assess the hazards and risks.

It is advisable to use suitable hearing protection such as earmuff s or ear plugs.

INFORMATION ON ELECTROMAGNETIC COMPATIBILITY -

Electromagnetic emissions from the

machine do not exceed the limits defi ned by the relative standards for the envisaged conditions of use.

Check that the power supply system is equipped with a thermomegnetic circuit breaker to protect

all conductors from short circuit and overloads.

Vibrations

- The mean frequency-weighted r.m.s. hand-arm acceleration value in normal cutting

conditions using correctly sharpened blades, is less than 2.5 m/sec

2

.

Test measurements were carried out in accordance with Standards EN ISO 5349-1 and EN ISO 5349-2.

Vibrations during real machine use may diff er from those declared as the total vibration value

depends very much on how the machine is used.

It is therefore necessary to identify the most appropriate safety measurements to safeguard the

operator based on estimated exposure times and real conditions of use.

Содержание 8.42.61.30

Страница 23: ...23 20 Kg...

Страница 31: ...31...

Страница 32: ...32 800 mm 900 950 mm 80 mm 80 mm 80 mm 24 24 A A A TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 33: ...33 250 mm 250 mm TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 34: ...34 1 2 3 4 5 6 3 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 36: ...36 1 2 3 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 37: ...37 45 0 15 30 2 3 4 5 45 0 15 30 1 TR 250 i TR 250 i Double cut TR 305 i...

Страница 38: ...38 45 0 15 30 4 45 0 15 30 1 3 3 45 0 15 30 4 45 0 15 30 2 TR 077...

Страница 39: ...39 45 0 45 3 2 1 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 40: ...40 45 max 5 4 0 45 0 45 0 45 45 0 45 0 TR 077 TR 250 i TR 305 i...

Страница 41: ...41 1 2 3 4 5 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 42: ...42 7 8 6 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

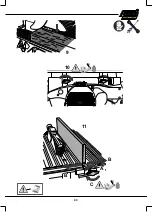

Страница 43: ...43 A C B B 10 11 9...

Страница 44: ...44 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 45: ...45 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 46: ...46 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 59: ...59 RU 2 5 2 UNI EN ISO 5349 1 5349 2...

Страница 60: ...60 BG 2 5 2 UNI EN ISO 5349 1 5349 2...

Страница 63: ...63 EL 2 5 m sec 2 UNI EN ISO 5349 1 5349 2...

Страница 75: ...75 1 5 6 8 2 sec 7 9 TR 250 i TR 250 i Double cut TR 305 i TR 077...

Страница 76: ...76 2 4 3 1 2 TR 077 TR 250 i TR250 iDouble cut TR 305 i TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 78: ...78 3 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 84: ...84 www femi it TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 86: ...86 1 1 2 3 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 87: ...87 1 4 7 8 6 6 5 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 88: ...88 2 1 4 4 2 2 3 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 89: ...89 2 5 6 7 TR 077 TR 250 i TR 250 i Double cut TR 305 i...

Страница 96: ...96 RU 1 2 1 2 RU 1 2 3 4 10 5 2 BG 1 2 1 2 BG 1 2 3 4 10 5 2...

Страница 118: ...118 RU 1 2 3 1 2 3 1 2 1 2 1 1 1 1 1 2 1 2 1 1 1 1 2 1 1...

Страница 119: ...119 BG 1 2 3 1 2 3 1 2 1 2 1 1 1 1 1 2 1 2 1 1 1 1 2 1 1...

Страница 122: ...122 EL 1 2 3 1 2 3 1 2 1 2 1 1 1 1 1 2 1 2 1 1 1 1 2 1 1...