- 8 -

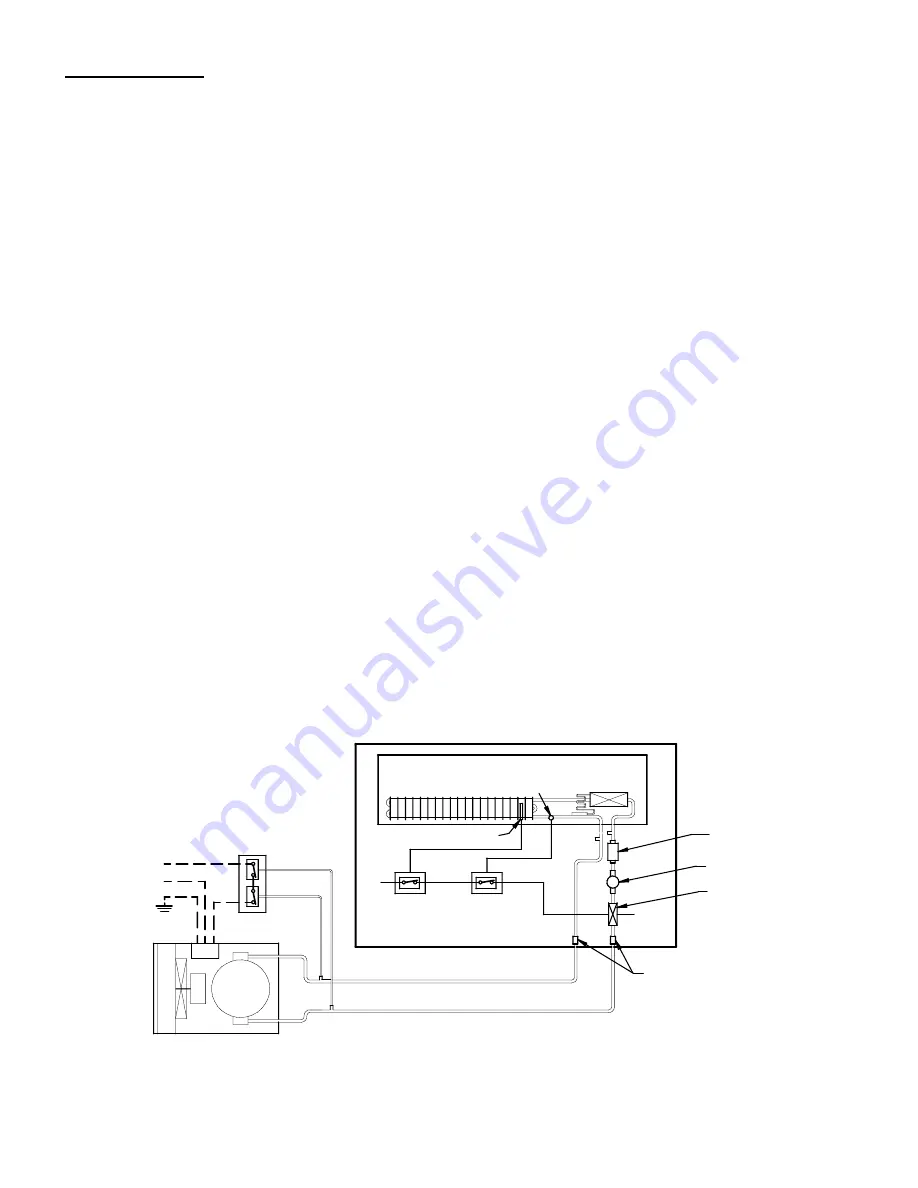

Remote Models

The remote models are designed to use 449 refrigerant and are shipped from the factory with the evaporator

coil, expansion valve, sight glass and refrigerant solenoid valve. A thermostat senses evaporator

temperature and opens and closes the refrigerant solenoid valve. The solenoid valve closes and shuts off the

refrigeration flow to the unit and initiates a pump down cycle. This will allow the remote low pressure

switch to open and shut off remote compressor. The temperature control may require some adjustment by

the installer for proper operation of unit. This unit also has a defrost timer that will shut the refrigeration

solenoid off a set number of times per day (set at the factory to 3 times per day) to insure a full defrost

occurs. The solenoid will remain off until either the off time is reached or until the temperature sensor on

the coil reaches a set temperature, whichever happens first

The condensing unit is optionally supplied from the factory for remote location installation. The

condensing unit supplied from the factory will require a high low pressure switch that must be mounted and

wired by the installer. The high low pressure switch must be wired in series with the compressor power

supply as shown in diagram below. A drier/filter must also be installed by installer.

1.

Mount condensing unit indoors as close to the remote display case as practical. The refrigeration line

should be as short as possible and must not exceed 30 feet.

2.

All refrigeration and/or electrical materials between the condensing unit and display case are to be

supplied by installing contractor.

3.

Route properly sized and designed refrigeration lines from the condensing unit to the cabinet.

Horizontal suction lines should be pitched downward towards the condensing unit at least ½” per 10’

run to aid the oil drainage. A “P” trap must be installed in the suction line at the foot of every riser to

insure oil return. Dry nitrogen must be used to flow through tubing while brazing refrigeration lines.

4.

The suction line must be insulated the entire length with Armaflex (or equivalent). Do not run liquid

line inside insulation with suction line.

5.

The remote high/low-pressure control must be mounted, wired and set pressures by the installer.

6.

Leak check the condensing unit, cabinet, and all connecting tubing. The cabinet and condensing unit

tubing should be checked to insure no leaks occurred during shipping or from rough handling.

Make certain all refrigeration valves are opened and evacuate system to 500 microns. Charge the

system with the refrigerant type specified on the data plates.

REMOTE

HIGH LOW

PRESSURE

CONTROL

LIQUID LINE

SUCTION LINE (INSULATED)

REMOTE

CONDENSING

UNIT

EVAPORATOR COIL

DISPLAY CASE

EXPANSION

VALVE

HIGH

LOW

LIQUID LINE

SOLENOID VALVE

SIGHT GLASS

DRIER/FILTER

FIELD CONNECTION

HOT

FUSED

POWER

SUPPLY

DEFROST

TIMER

HOT

DEFROST

TERMINATE

TEMPERATURE

CONTROL

NEUT.

TEMP. CONTROL PROBE