888-999-7715

www.FastListParts.com

7

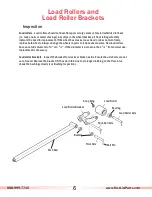

Load Rollers and

Load Roller Brackets

Removal

Tip: We recommend servicing one load roller assembly at a time, using the other assembly as a reference.

Load rollers

Standard height

- Turn the jack over onto its side. Remove one of the snap rings and punch the axle out

of the wheel and bracket. (10 minutes)

Lowered height

- Turn the jack over onto its side. Remove the roll pin and punch the axle out of the wheel

and bracket.

(10 minutes)

Load roller brackets

Standard height

- Turn the jack over onto its side and remove the load roller. Remove the snap ring on the

pivot axle and punch it out of the frame and bracket. Remove the snap ring and drive the push rod axle

out of the bracket.

(15 minutes)

Lowered height

- Turn the jack over onto its side and remove the load roller. Remove the roll pin securing

the pivot

axle in place and punch the axle out. Remove the roll pin fastening the push rod axle to the bracket and

drive the axle out.

(15 minutes)

Installation

Load roller brackets

Standard height

- With the jack on its side, insert the axle through the bracket and the push rod. Secure

it in place with the snap rings. Attach the bracket to the frame by inserting the pivot axle through the

frame and bracket. Secure in place with the snap rings. Install the load roller. Insert the end of the axle

without the knurl first for easier installation.

(15 minutes)

Lowered height

- With the jack on its side, insert the push rod axle into the bracket and push rod. Secure

it in place with the roll pin. Fasten the bracket to the frame by inserting the pivot axle through the frame

and bracket and securing

the axle in place with the roll pin. Install the load roller. (15 minutes)

Load rollers

Standard height

- With the jack on its side, insert the axle through the bracket and wheel. Secure it in

place with the snap ring. Insert the end of the axle without the knurl first for easier installation.

(10 minutes)

Lowered height

- With the jack on its side, insert the axle through the bracket and wheel. Secure the axle

in place by replacing the roll pin. (10 minutes)

Содержание Rol-Lift E Series

Страница 2: ...www FastListParts com 2 888 999 7715...