www.FastListParts.com

12

888-999-7715

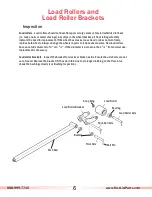

Lifting Link

Inspection

Check lifting link for out-of-round holes, cracks in welds, or bent ears. If any of these conditions exist,

replace the lifting link. We suggest that you work on one side of the jack at a time, so you can use the

other side as a reference. The T Series standard height uses an eccentric for adjustment and the

lowered height uses an eye bolt for adjustment. Both standard and lowered height of the E Series

uses an eye bolt, as well.

Removal - T Series

Standard height

- Pump the jack up to its maximum height. Remove the snap ring under the A-Frame

that secures the upper thrust bearing assembly on the ram to the jack. Lift the jack off of the ram and

pivot the hydraulic unit away from the frame. Remove the shoulder bolts fastening the traverse to the

lifting link, by driving out their roll pins. Remove the hydraulic unit and traverse assembly as one

piece. Turn the jack over so that the undercarriage is facing up. Loosen the set screw that holds the

eccentric in adjustment. Remove the snap ring on the eccentric, and pull the eccentric out through

the access hole in the side of the frame. Remove the snap ring on the lifting link shaft. Use a hammer

and punch to drive the shaft out far enough to grip it on the other side, and pull it out. (45 minutes)

Lowered height

- (see E Series Lifting Link Removal, below)

Removal - E Series

Standard and Lowered height

- Pump the jack up to its maximum height. Remove the snap ring

under the

A-Frame that secures the upper thrust bearing assembly on the ram to the jack. Lift the jack off of the

ram and pivot the hydraulic unit away from the frame. Remove the shoulder bolts, fastening the

traverse to the lifting link, by driving out their roll pins. Remove the hydraulic unit and traverse

assembly as one piece. Turn the jack over so that the undercarriage is facing up. Remove the pivot

axle. Remove the snap ring on the axle for standard height jacks, or the roll pin on lowered height

jacks. Then remove the eye bolt (with the push rod still attached) by removing the snap ring that

fastens it onto the lifting link. Remove the snap ring on the lifting link shaft. Use a hammer and

punch to drive the shaft out far enough to grip it on the other side, and pull it out. (45 minutes)

Содержание Rol-Lift E Series

Страница 2: ...www FastListParts com 2 888 999 7715...