CH180HF

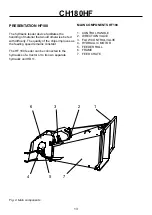

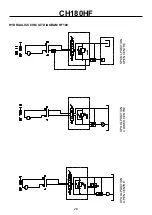

21

1

5

4

3

2

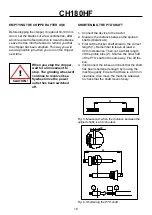

PERIODIC MAINTENANCE

Always disengage the PTO

and stop the tractor and

chipper fully before

maintenance or repair work.

Ensure that the disk is fully stopped before

inserting anything inside the feed chute.

Lock the disk before maintenance or repairs.

Park the chipper on hard, level ground to

avoid it falling over.

Wear protective gloves when handling

knives or anvils.

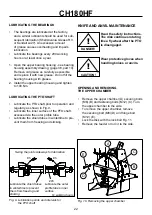

PERIODIC INSPECTIONS

With new machines, check the mounting bolts

for tightness after the first operating hour,

tightening them if necessary. T

ightening torques are shown in table.

Check the mounting bolts for tightness once a

week.

The knife-to-anvil clearance is adjusted to the

specified values. For instructions on adjusting

the clearance, see Adjusting the knife-to-anvil

clearance.

•

•

•

Item

Width across flats,

mm (inches)

Tightening torque, Nm

(lbf)

1. Check the knife bolts for tightness.

17 mm (11/16”)

60 (44

3

/

16

)

2. Check the bearing housing bolts for

tightness on both sides..

22 mm (14/16”)

100 (73

11

/

16

)

3. Check the anvil bolts for tightness.

24 mm (15/16”)

200 (147

3

/

8

)

4. Check the clearance between knives and

vertical anvils.

19 mm (3/4”)

1,2 - 1,5 mm (0,02 - 0,06”)

5. Check the bearings for radial clearance.

0,02 - 0,03 mm (0,008 - 0,0012”)

Fig. 15. Checklist for tightening and checking clearances

WARNING!

!

Содержание CH180HF

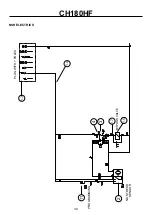

Страница 30: ...CH180HF 30 11 4 3 2 1 3 1 7 1 5 1 4 NSH ELECTRICS PLUG WITH 7 POLES BY PASS VALVE PROGRAMMING NO STRESS SENSOR ...

Страница 32: ...CH180HF 32 1 10 9 8 7 6 4 3 2 11 18 17 16 15 14 13 5 12 14 15 14 13 11 19 03517200 HYDRAULICS HF180 ...

Страница 44: ...CH180HF 44 10 12 11 1 9 8 7 6 5 4 3 2 19 18 17 16 15 14 13 20 24 23 22 21 8 03520010 FEED CHUTE F180 ...

Страница 51: ......