13

GB

KJ 45

KJ 45

Revision - 04

Date 10-2008

TOOL IDENTIFICATION

The riveting tool

KJ45

is identifi ed by a label showing the name and

the address of the manufacturer and the model also. If any service is

requested please make reference to the data shown on the label.

GENERAL NOTES AND USE

The tool can be employed only for threaded inserts

M4÷M12

.

The

KJ45 hydropneumatic system

assures more power than the

pneumatic system used for other models. That means a reduction in the

problems due to the wear and tear of the components, therefore, there

will be an increase in reliability. The technical solutions adopted reduce

the dimensions and the weight of the tool, which is very handy for these

reasons. The possibilities of leakage from the oil-dynamic system, are

eliminated by some sealed gaskets, which solve this problem.

Name and address

of manufacturer

Model

TECHNICAL DATA

• Working pressure

.............................................................

6 - 7 BAR

• Min. int. diam. of the compressed air

feeding

hose

...........................................................

ø min. = 8 mm

• Max free air consumption per cycle ........................................

11 NI

• Force (6 BAR) .......................................................................

28 KN

• Noise level......................................................................

< 75 db(A)

• Weight (with equipment for M10) ..........................................

2.9 Kg

• Working temperature ........................................................

-5°/+50°

• Root mean square in total acceleration

frequency (Ac) to which

the arms are subjected ..............................................

< 2.5 m/sec2

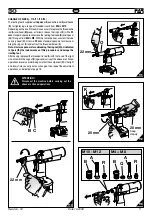

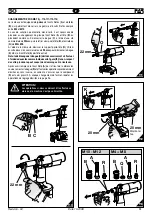

Ø 50

Ø 130

296*

124*

Ø 27

312

M

P

G

E

F

A B C D

L I H N

O

*

with M10 tie rod

MAIN COMPONENTS

A)

.............................................................................. Threaded tie rod

B)

................................................................................................Head

C)

.................................................................. Ring-nut clamping head

D)

.........................................................................Control push-button

E)

.............................................................Compressed air connection

F)

..................................................................... Pressure control valve

G)

............................................................................ Protection bottom

H)

............................................................................. Pneumatic motor

I)

..................................................................................... Oil tank plug

L)

........................................................................Balancer connection

M)

.....................................................................Stroke-adjusting knob

N)

............................................................................... Stroke indicator

O)

..........................................................................Tube carrying head

P)

.................................................................... Forced unscrewing rod

Содержание KJ45

Страница 79: ......