17

ENGLISH

18

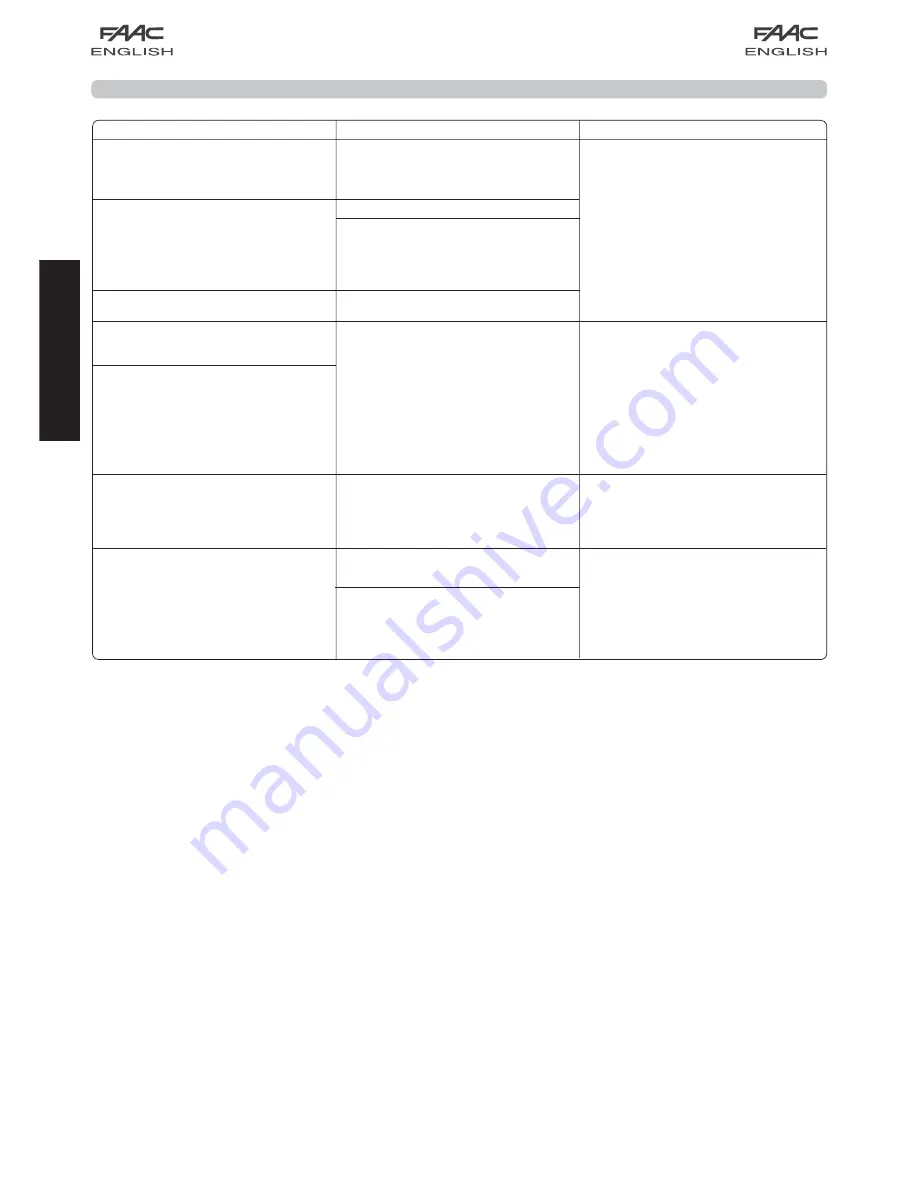

. TROUBLESHOOTING

Trouble

Possible causes

Solution

When the learning procedure is started,

the SET UP LED flashes but the automated

system does not perform any

manoeuvre

The STOP and FSW safety devices are

enabled also during the learning stage.

Non-connection or wrong connection

prevents the operator from working

Check the LEDs’ status following the

instructions of the “Inputs status LEDs”.

Check the connections shown in fig. 27

The automated system does not

perform any movement

STOP command enabled

The automated system opens the door

but does not close it

FSW safety devices engaged

The Fail-Safe function is enabled, but the

NC contact of the devices connected

to the FSW input does not open during

test by the unit before the manoeuvre

is started

Learning is not finished correctly and the

SET UP LED flashes to signal a fault

The automated system frequently

reverses motion during the opening

and/or closing manoeuvre

-The automated system detects that

the door movement is too difficult.

- If you are using manual adjustment of

force, the set thrust could be insufficient.

Check the balance of the door and

make sure that it moves without too much

friction. Move the door manually, using

the rod fitting on the door, and check

if the movement is smooth and does

not require too much traction or thrust.

Execute a new learning cycle. If necessary,

vary the thrust force (if using manual

adjustment) or start learning with a ma-

ximum thrust of 1000N.

It is difficult to release the automated

system while the door is closed

Too much mechanical load on the release

system with the door closed

Run a new learning cycle and,

when over, lighten the closing thrust,

commanding the carriage to withdraw

as described in paragraph 11.2.

The SET UP LED flashes to signal a fault

status

The learning cycle did not finish

positively.

Run a new learning cycle

DS1’s switch No. 3 (automatic/manual

adjustment of force) was shifted and a

new learning cycle was not executed.

Содержание D1000

Страница 1: ...D1000 D1000...