22

b) Check kill circuits. Run engine at one-third throttle,

disengage

parking

brake and

raise off

of seat (but do not get off of machine) engine

must

stop

after approx. 1/2 second has elapsed (seat has time delay kill switch

to prevent cut-outs on rough terrain).

Run engine at one-third throttle,

engage PTO

and

raise off

of seat (but do

not get off of machine) engine

must stop

after 1/2 second has elapsed.

Run engine at one-third throttle, with brake disengaged, move levers in and

raise off seat (but do not get off of machine) engine

must stop

after 1/2

second has elapsed.

Again, run engine at one-third throttle, brake

engaged,

and move

left

motion control lever in

- engine

must stop.

Repeat again moving the

right lever in

, then moving

both levers in

-

engine

must stop

whether operator is

on seat or not

.

NOTE: If machine

does not

pass any of these tests, do not operate.

Contact your authorized EXMARK SERVICE DEALER.

IMPORTANT: It is essential that operator safety mechanisms be connected

and in proper operating condition prior to use for mowing.

4.1.7

Check rollover protections systems (roll bar) pins

Service Interval: Daily

a) Make sure latch pin and hair pin are fully installed and lanyard is in good

condition.

4.1.8

Check for loose hardware.

Service Interval: Daily

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Visually inspect machine for any loose hardware or any other possible

problem. Tighten hardware or correct the problem before operating.

4.1.9

Service air cleaner.

Service Interval: See Engine Owner’s Manual

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

See Engine Owner’s Manual for cleaning instructions.

4.1.10 Change engine oil:

Service Interval: See Engine Owner’s Manual

.

NOTE: Change oil and filter after first five (5) hrs. of operation. Follow

engine manufacturer’s recommendations for future oil changes.

a)

Stop engine, wait for all moving parts to stop, and remove key.

b)

Drain oil while engine is warm from operation.

c) Oil drain hose is located on left hand side of the engine.

Place pan under machine to catch oil. Remove plug from end of oil drain

hose. Allow oil to drain, then reinstall plug.

d)

Replace the oil filter

as per the Engine Owner’s Manual. Clean around oil

filter and unscrew filter to remove.

Before reinstalling new filter, apply a thin coating of oil on the surface of the

rubber seal. Turn filter clockwise until rubber seal contacts the filter adapter

then tighten filter an additional 2/3 to 3/4 turn.

e)

Clean around oil fill cap and remove cap. Fill to specified capacity and replace

cap. Use oil recommended in engine owner’s manual.

DO NOT

overfill.

f)

Start the engine and check for leaks. Stop engine and recheck oil level.

Содержание Lazer ZCT

Страница 1: ...For Serial Nos 600 000 Higher Part No 109 2279 Rev B ...

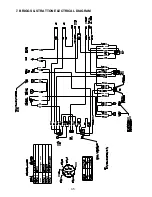

Страница 40: ...35 7 BRIGGS STRATTON ELECTRICAL DIAGRAM ...

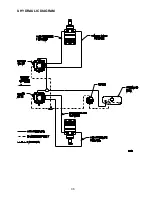

Страница 41: ...36 8 HYDRAULIC DIAGRAM ...

Страница 44: ... 39 NOTES ...

Страница 45: ... 40 NOTES ...

Страница 46: ... 41 SERVICE RECORD Date Description of Work Done Service Done By ...

Страница 47: ... 42 ...