Maintenance

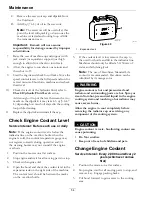

WARNING

Engine coolant is hot and pressurized and

radiator and surrounding parts are hot. Spray

or steam from hot, pressurized liquid in the

engine cooling system and touching a hot

radiator may cause severe burns.

Allow the engine to cool completely before

removing the radiator cap or servicing any

component of the cooling system.

CAUTION

Engine coolant is toxic. Swallowing coolant

can cause poisoning.

•

Do Not swallow.

•

Keep out of reach of children and pets.

4.

Drain coolant when engine is cool. Remove

the radiator cap, place a pan under the radiator,

and remove the drain plug at the bottom of the

radiator.

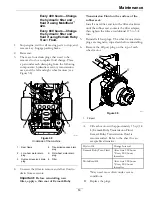

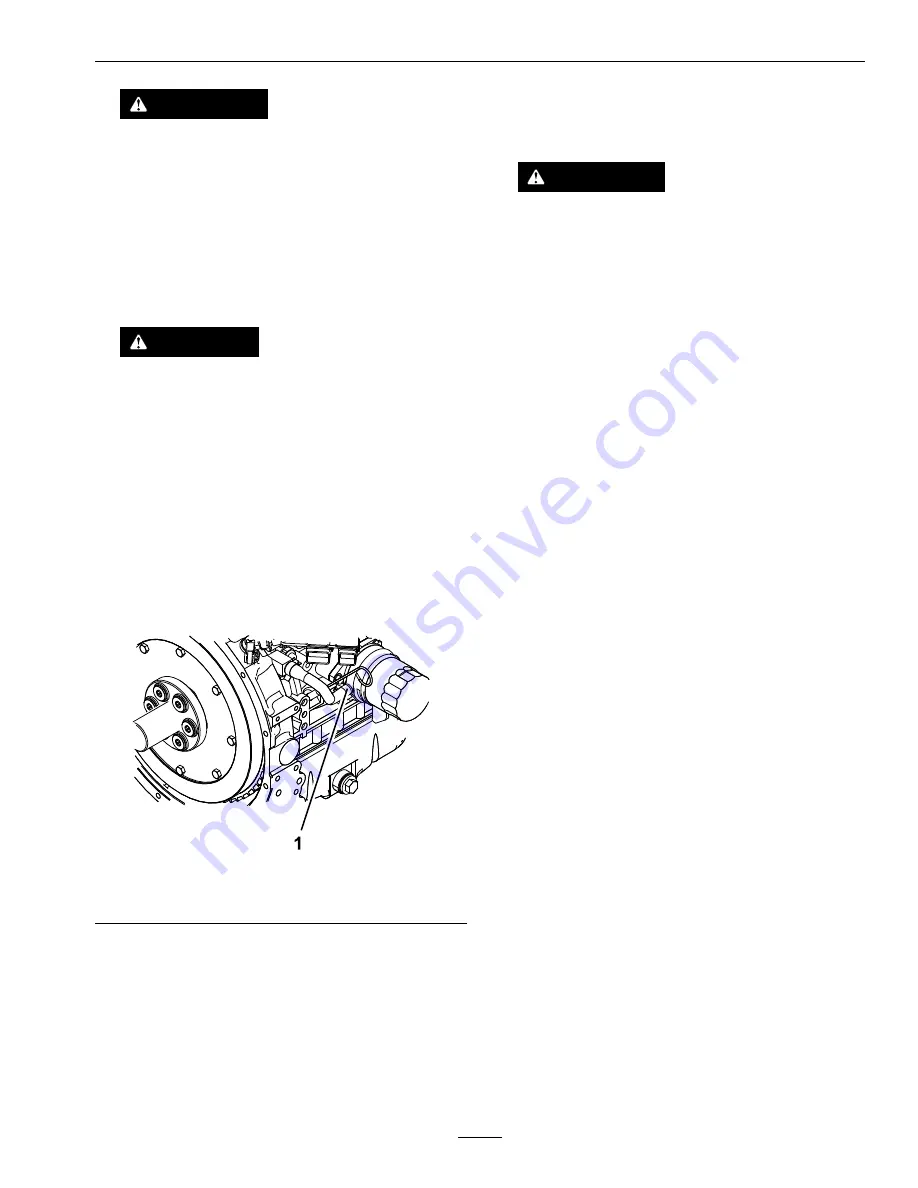

5.

Remove the coolant hose from the oil cooler and

drain the coolant from the engine block (reference

Figure 41).

g233651

Figure 41

1.

Coolant hose

6.

Reinstall all drain plugs and hoses.

7.

Fill radiator with a 50/50 mix of water and

ethylene glycol.

Note:

The use of Havoline

®

Xtended Life

coolant is recommended.

Allow some room (approximately 1/2 inch (12.7

mm)) for expansion. Add 50/50 coolant mix to

overflow bottle on the left side of the engine as

required to bring the level up to the indicator line

on the bottle.

WARNING

Engine compartment contains open belt

drives, fans, and other rotating components

that can cause injury. Fingers, hands, loose

clothing, or jewelry can get caught by the

rotating fan and drive shaft.

•

Do Not operate machine without the

covers in place.

•

Keep fingers, hands, and clothing clear of

rotating components.

•

Shut off engine, wait for moving parts to

stop, engage parking brake and remove

key, before performing maintenance.

8.

Operate engine until the engine thermostat opens

and coolant is circulating through the radiator

core. As air is purged from the engine block and

the coolant level drops, add additional coolant to

the radiator.

9.

When the radiator is completely full and no

additional coolant can be added, continue running

and install the radiator cap. Make sure that the

cap is completely seated by pressing down firmly

while turning until the cap stops. Once the cap is

installed, the engine may be stopped.

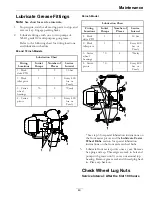

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

Caster wheel spacer nuts.

Mobil HTS Grease (Or

Food-Grade Anti-seize)

Mobil HTS grease (or food-grade anti-seize) is used

in the following locations:

•

Between the cutter housing spindle and bearings.

•

Between the cutter housing spindle and sheave.

Copper-Based Anti-seize

Copper-based anti-seize is used in the following

location:

55

Содержание Lazer Z Series

Страница 1: ...LAZER Z DIESEL For Serial Nos 402 082 300 Higher Part No 4503 837 Rev B ...

Страница 74: ...74 ...