Operation

mm) clearance to the ground to minimize gouging

and roller wear or damage.

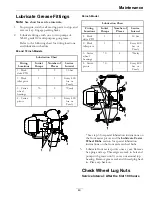

g035118

Figure 19

For cutting heights above 3.5 inches (90 mm) use the

bottom hole. The rollers will still be effective against

scalping.

1.

Anti-scalp roller

mounting bracket

2.

Cutting height

For Maximum Deck Flotation,

place the rollers

one hole position lower. Rollers should maintain

1/4 inch (6.4 mm) clearance to the ground.

Do

Not

adjust the rollers to support the deck.

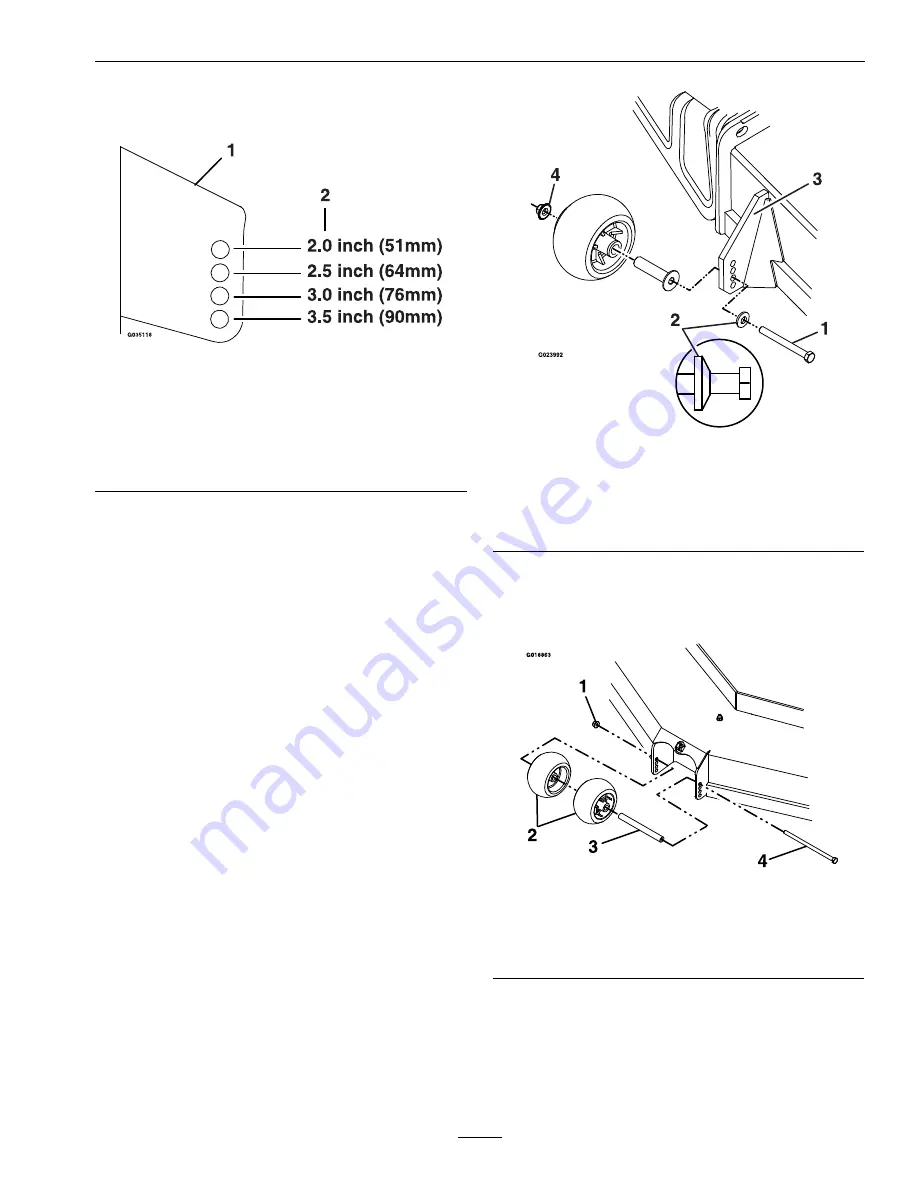

7.

Reinstall the mounting hardware:

•

Side Discharge Models:

A.

Be sure the roller bolts are installed with

the spring disc washer between the head

of the bolt and the mounting bracket (see

Figure 20).

B.

Torque the 3/8 nyloc nut to 50–55 ft-lb

(68-75 N-m).

g023992

Figure 20

1.

3/8-16 X 3 3/4 Grade 8

bolt

3.

Front right anti-scalp

bracket shown

2.

Spring disc washer

(cone towards bolt head)

4.

3/8 nyloc-torque to 50-55

ft-lb (68-75 N-m)

•

Rear Discharge Models:

Torque the 3/8 nyloc nut to 30-35 ft-lb (41-47

N-m) (see Figure 21).

g018862

Figure 21

1.

3/8 nyloc-torque to 30-35

ft-lb (41-47 N-m)

3.

Spacer

2.

Anti-scalp rollers

4.

Bolt

The 96 inch deck has 13 anti-scalp roller locations to

adjust see Figure 22.

35

Содержание Lazer Z Series

Страница 1: ...LAZER Z DIESEL For Serial Nos 402 082 300 Higher Part No 4503 837 Rev B ...

Страница 74: ...74 ...