12

Instruction Manual for

Power Cooler

Air Blast

12/2

A10

Quick release coupling, coolant return from welding torch

B10

Quick release coupling, coolant supply to welding torch

C10

Viewing window (coolant level)

D10

Filler inlet coolant (with screwcap lid and sieve)

E10

Current overload cut-out for coolant pump

12.4

Commissioning

Please read the safety information on pages 3 + 4 before proceeding further

Operating environment

The working life of the cooling unit can be seriously affected, by various amounts, of Dirt, Dust,

Acids, Corrosive gases, or metallic particles being present in the air of the working environment.

Position the machine so that the Air flow into and out of the unit is completely unrestricted.

Coolant

The machine becomes from factory with a coolant-minimum filling KF23E-10 delivered.

With the coolant KF23E-10 is guaranteed antifreezes to –10 °C!

Coolant stood examine and if necassary up to the upper shop-window of the tank (C10) coolants

KF23E-10 (Article No.: if accessory see) refill.

Using a mixture of other coolants, or using a coolant other than one prescribed above will

void the manufacturers guarantee.

The filter must be in the filler rack when filling the unit.

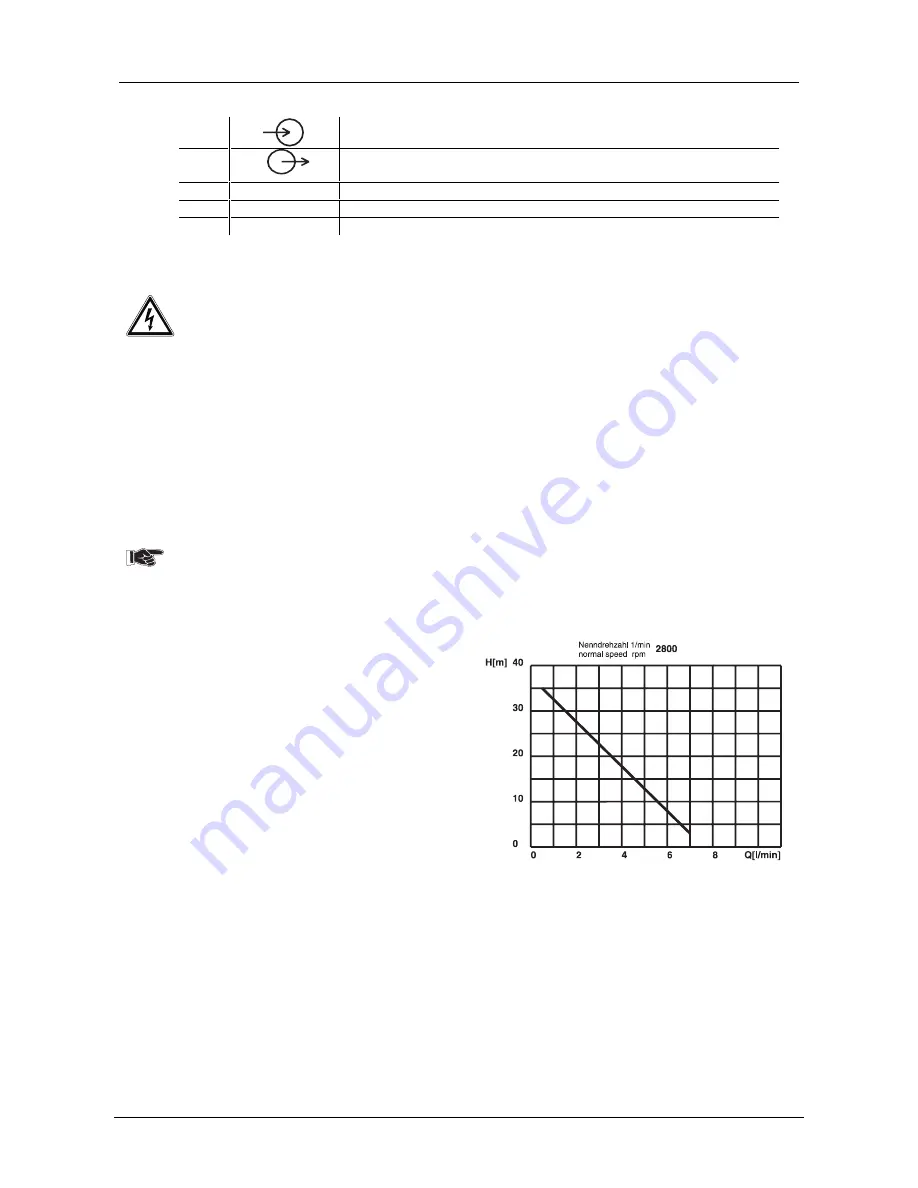

Characteristic of the integrated water pump

Putting:

H

[

in m

]

conveyor

high

P

[

in W

]

submitted pumping power

Q

[

l/min

]

conveyor

quantity

Q

[

m

3

/h

]

conveyor quantity

The power cooler is now ready for use!

Содержание inverter TIG 150 DC

Страница 46: ...13 Schaltpl ne Circuit Diagrams 13 1 13 1 inverter TIG 150 DC Schaltpl ne befinden sich ebenfalls im Ger t...

Страница 47: ...13 Schaltpl ne Circuit Diagrams 13 2 13 2 inverter TIG 200 DC powerSinus...

Страница 48: ...13 Schaltpl ne Circuit Diagrams 13 3 13 3 inverter TIG 200 DC powerSinus power K hlmodul...

Страница 49: ...13 Schaltpl ne Circuit Diagrams 13 4 13 4 inverter TIG 250 300 DC...