- 29 -

7. Inspection and Maintenance

7.1. General information

Routine inspections and maintenance work must be carried out to keep the hydraulic grab in the best

operating condition. The following sections list the inspection and maintenance intervals, check points over

the grab and carrier.

WARNING!

Read carefully and follow all safety regulations concerned with maintenance of the grab.

Refer to page 8,

”1.4. Safety information for maintenance of the grab”.

Whenever maintenance work is carried out, keep always following instructions.

1. Park the carrier on a firm and flat ground.

2. Close the grabs of the grab completely.

3. Lower the grab to ground and put the grab on a rigid and clean support.

4. Lower the engine speed to the lowest idle position.

5. Wait for at least 10 minutes to allow the residual pressure in the grab be released.

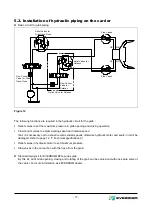

6. Turn the stop valves to

“OFF” position

DANGER!

Never put your body into the open grabs.

Risk of death or serious injury!

Followings are the basic inspections to be checked always :

Check, whenever inspecting, if there is a crack at the welded part of the grab (visual inspection).

Check, whenever inspecting, if there are oil leaks at the hydraulic components or the hydraulic

connections of the grab.

Check, whenever inspecting, if all fasteners such as bolts, nuts and snap-rings come loose, and retighten

them to the prescribed tightening torque, if necessary. Broken parts must be replaced immediately. Refer

to page 31,

“7.3. Tightening torques” for detail instructions.

In order to prevent possible damages to the grab from unallowed maintenance work, please keep following

instructions :

The hydraulic components of the grab - such as hydraulic cylinders, speed-up valve, rotation motor, etc. -

are precision made hydraulic elements. These parts are strongly recommended to maintain by authorized

EVERDIGM service.

Absolute cleanliness and great care are basic and essential matters in handling of any hydraulic

components. Dirt is the worst enemy in hydraulic system.

Sealing components such as packings, O-rings and plugs in the hydraulic system should be oiled with

very clean oil before assembly.

DANGER!

High pressure can be maintained in hydraulic cylinders and hoses long after the system has

been shut down. This residual pressure can cause hydraulic oil or parts such as plugs to

shoot out at high speed if the pressure is not released completely.

Содержание EPG05

Страница 1: ...OPERATION MAINTENANCE MANUAL Multi Purpose Grab Document No MSAGUS 0005 Revision Date 2014 09 23...

Страница 36: ...36 Notes...

Страница 37: ...37 Notes...