- 22 -

6. Operating the grab

6.1. Preparation for safe and correct operation

After whole installing procedure as described in the previous chapter, the grab is ready to operate. However,

before starting up the grab, please make sure the followings :

mechanical connection between the grab and the carrier

locking status of the mounting pins

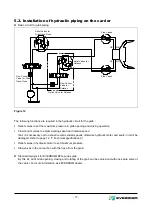

hydraulic connections between the grab and the carrier

exact setting of the relief pressure

no oil leaks from the hydraulic connections and any parts of the grab

no defective or loosened parts of the grab

cracks, wear, loss, etc.

Check the followings moving the grab :

corresponding the grab movements and the rotating direction with the appropriate actuating

switches in the carrier

‟s cab

smooth opening and closing of the grabs

smooth rotating of the grab

no abnormal sound and no vibration during the operation

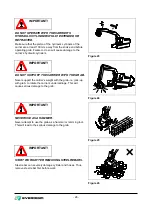

WARNING!

Read carefully and follow all safety regulations concerned with the preparation for safe

operation. Refer to page 6,

”1.2. Preparation for safe operation”.

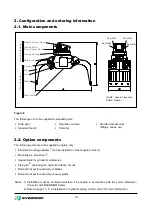

6.2. Greasing

Apply grease to every grease nipple

– marked with the “Greasing Port” label – at the joint pins and slewing

bearing of the grab using recommended greases.

Recommended greasing Interval : Every 2 hours

4 ~ 5 strokes from a grease gun to each greasing nipples are sufficient in each case

Adapt greasing interval and amount of grease to working conditions

Insufficient greasing may cause abnormal wear of the joint pin or slewing bearing

Grease with the following properties are recommended:

No dropping point (or very high, over 250

°

C / 480

°

F)

Max. working temperature over 150

°

C / 300

°

F

Min. working temperature under lowest ambient temperature

Additives : molybdenium disulphide (MoS

2

), graphite or equivalent

Grade (thickness) NLGI 0~2

Water resistant

Содержание EPG05

Страница 1: ...OPERATION MAINTENANCE MANUAL Multi Purpose Grab Document No MSAGUS 0005 Revision Date 2014 09 23...

Страница 36: ...36 Notes...

Страница 37: ...37 Notes...