ISSUE 1/Original version/March 2013

23

23

CE/EMC DECLARATION OF CONFORMITY

DECLARING:

EUROBOOR BV

Kryptonstraat 110

Zoetermeer

The Netherlands

that the following Appliance complies with the appropriate basic safety and health requirements of

the EC Directives based on its design and type, as brought into circulation by EUROBOOR BV.

Designation/ function

Magnetic Drilling Machine

Type

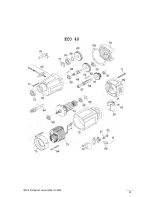

ECO.40/2

Ratings and principal

230-240V, 50/60Hz, Class I

Characteristics

ECO.40/2 | 1050W | N0: 720/1300 minˉ¹

Applicable EC Directives

Machinery Directive 2006/42/EC

Relevant standard(s) /

EN 55014-1:2006/+A1:2009/+A2:2011

Specification(s) / Directive(s)

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006/+A2:2009/+A2:2009

EN 61000-3-3 :2008

EN 61000-3-11 :2000

EN 61029-1 :2009+A11:2010

EN ISO 12100:2010

Additional used EC Directives

EMC Directive (2004/108/EC)

Verification Issuing Office Name

INTERTEK Testing Services

Albert Koster

Managing Director