ISSUE 1/Original version/OCT 2013

17

17

ADJUSTMENT OF SLIDE

An essential requirement of the machine is that the slide can move in a smooth and controlled

manner, free of lateral movement and vibration.

This situation can be maintained by periodic adjustment of the slide and is accomplished in the

following manner:

1.

Place the machine in an upright position and, by means of the capstan, raise the slide to its

highest position. Clean the brass rail strips and apply a small amount of light machine oil to

the wear surfaces.

2.

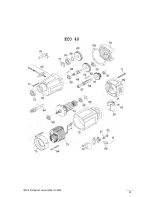

Commencing with the top screw, loosen both setting nut (#4 on spare part drawing) with

included wrench 8 and the setting screw (#5 on spare part drawing) with included Allen key

2.5. Then gently feed in setting screw until slight resistance is encountered. Follow your way

down adjusting all setting nuts and screws.

3.

Operate the slide up and down a few times to test the movement and make any further

necessary adjustments. Try to ensure that all the screws are exerting a uniform pressure on

the slide from top to bottom. A perfectly adjusted slide will operate freely up and down

without any sideways movement.

REPAIR, MODIFICATION AND INSPECTION

Repair, modification and inspection of Euroboor Magnetic drilling machines must be done by

EUROBOOR or an EUROBOOR authorized dealer. The spare parts list will be helpful if presented with

the machine to the Euroboor dealer for service when requesting repair or other maintenance.

Euroboor machines are constantly being improved and modified to incorporate the latest

technological advancements. Accordingly, some parts (i.e. part numbers and/or design) may be

changed without prior notice. Also, due to Euroboor's continuing program of research and

development, the specifications of machines are subject to change without prior notice.