ISSUE 1/Original version/OCT 2013

11

11

EXTENSION CABLE

If an extension cable is required, use an approved 3-core extension cable suitable for the power input

of this tool (see technical data).The minimum conductor size is 1.5 mm²; the maximum length is 30

meter. When using a cable reel, always unwind the cable completely.

ASSEMBLY AND ADJUSTMENTS

WARNING:

To reduce the risk of injury, turn unit off and disconnect machine from power

source before installing and removing accessories, before adjusting or changing set- ups or

when making repairs. Be sure the switch is in the OFF position. An accidental start-up can

cause injury.

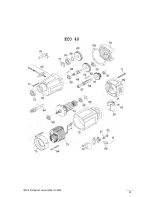

PREPARATION OF THE MACHINE (FIG. 1)

1.

Assemble the feed handle.

2.

Mount the drill guard.

3.

Fit the lubrication system as necessary.

4.

Place the machine on a clean, level and solid surface. Remove any particles that will obstruct

full contact between the magnetic stand and the mounting surface.

5.

Fit the safety chain (in vertical or overhead drilling applications).

MOUNTING THE DRILL GUARD (FIG. 1)

The guard protecting against chippings and accidental contact must always be mounted during

operation.

1.

Hold the guard in front of the magnet, aligning the slots in the guard with the holes in the

magnet.

2.

Fit the screws into the hole located in the side of the magnet.

WARNING:

Always use the Safety guard.

FITTING THE LUBRICATION SYSTEM (FIG. 1)

The lubrication system can be used for horizontal drilling applications (the drill being used vertically).

•

Hold the cooling tank against the bracket on the slide and push it in its place.

•

Connect the hose to the nipple on the spindle drive shaft.

In order to use the lubrication system, it must be filled with a sufficient amount of cutting fluid.

1.

Make sure the flow regulator is closed.

2.

Unscrew the cap.

3.

Fill the container with cutting coolant.

4.

Screw the cap back on.

WARNING:

Do not use the lubrication system in vertical or overhead drilling applications.

Instead use Euroboor cutting paste

FITTING THE SAFETY CHAIN

1.

Pass the safety chain through the opening near the handle.

2.

Wrap the chain around the work piece.

3.

Securely tighten the chain.

WARNING:

Always use the safety chain when using machine vertically or in up-side-down

position.