MC404-Z

Document Version: 1.05

© 2021 All rights reserved.

8

be defined to be used by the controller for end of travel limits, registration, datuming and

feedhold functions if required. The MC404-Z can have up to 512 external Input and Output

channels connected using DIN rail mounted CAN I/O modules. These units connect to the

built-in CANbus port.

Communications

A 10/100 base-T Ethernet port is fitted as standard and this is the primary communications

connection to the MC404-Z. Protocols supported include Telnet (Client and Server), Modbus

TCP (Client and Server), Ethernet IP (Client) and the TrioPCMotion DLL/ActiveX channel.

The MC404-Z has one built in RS232 port and one built in duplex RS485 channel for simple

factory communication systems. Either the RS232 port or the RS485 port may be configured

to run the Modbus or Hostlink protocol for PLC or HMI interfacing.

If the built-in CAN channel is not used for connecting I/O modules, it may optionally be used

for CAN communications. E.g. DeviceNet, CANopen etc.

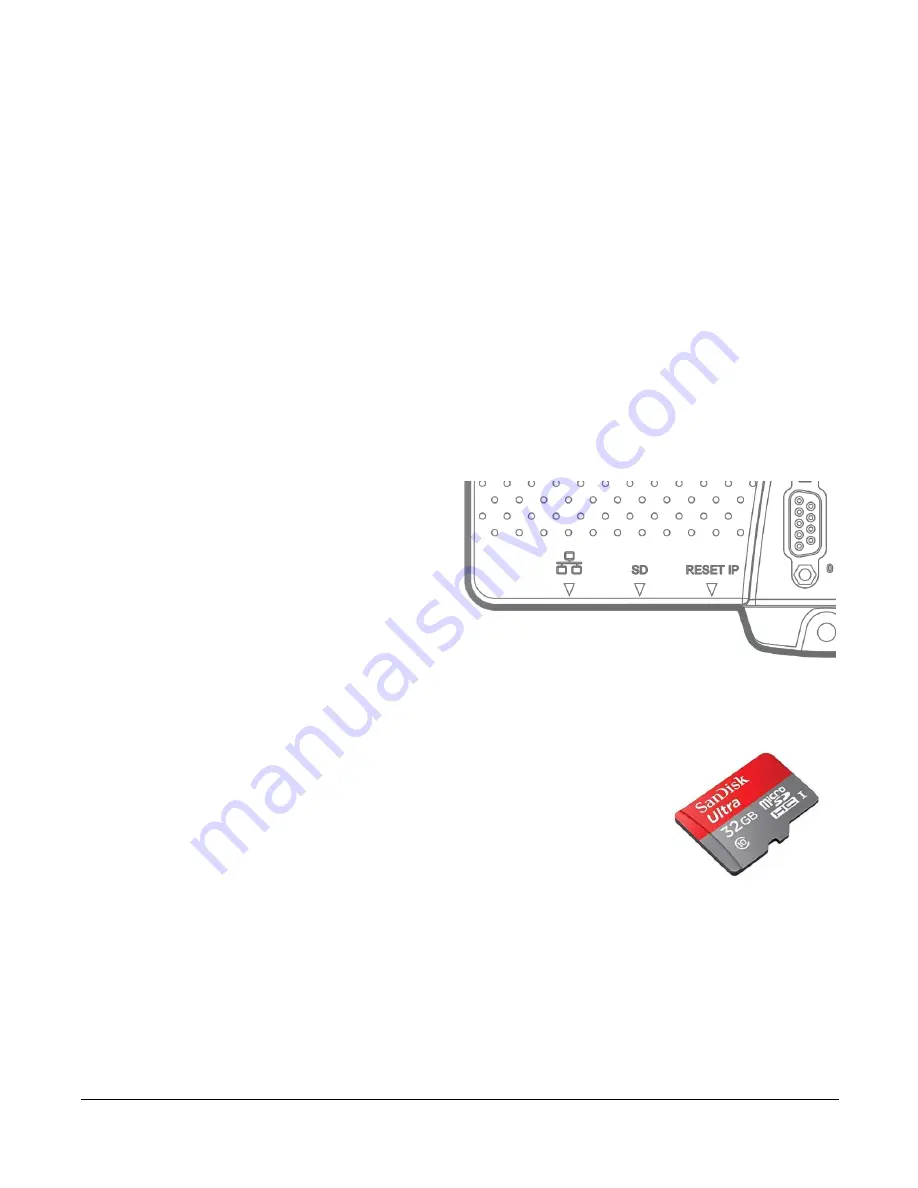

IP Address reset

To reset the IP _ ADDRESS, IP _ GATEWAY

and IP _ NETMASK to their default values

press the IP reset button located next to

the SD card slot and power cycle the

controller while keeping the button

pressed.

The factory default IP address is

192.168.0.250. This can be changed using

the ETHERNET or IP_ADDRESS commands via

Motion Perfect.

Removable storage

The MC404-Z has a micro-SD Card slot which allows a simple means

of transferring programs, firmware and data without a PC

connection. Offering the OEM easy machine replication and servicing.

The memory slot is compatible with a wide range of micro-SD cards

up to 32 GBytes using the FAT32 compatible file system.

Axis positioning functions

The motion control generation software receives instructions to move an axis or axes from

the Motion-iX or IEC 61131-3 language which is running concurrently on the same processor.

The motion generation software provides control during operation to ensure smooth,

coordinated movements with the velocity profiled as specified by the controlling program.

Linear interpolation may be performed on groups of axes, and circular, helical or spherical

interpolation in any two/three orthogonal axes. Each axis may run independently, or they

may be linked using interpolation, electronic gearboxes and simple kinematics.