10

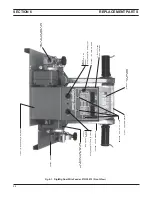

B. Torch Connections

Attach torch gas hose to gas connections. Plug in torch

switch cables and lock by twisting. After inserting con-

duit liner (if used) and attaching wire outlet guide of

correct size, connect wire feed conduit to welding head

clamp and lock in place. Attach water hose (if used) to

wire feeder. Connect torch power cables to power

source, or to power cable adaptor block (with a second

cable from that stud to the power source).

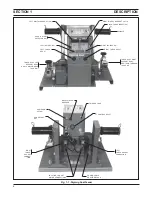

C. Installing Feed Roll

1. Release the clapper on the accessory support as-

sembly (Figure 6-5) by disengaging the retainer from

the clapper fork.

2. Remove thumbscrew, belleville washer, and flat

washer from the feed roll shaft.

3. Slip the feed roll on the shaft, engaging the key. Be

sure to observe this “THIS SIDE OUT” marking on the

feedroll.

4. Reassemble flatwasher, belleville washer, and thumb

screw, tightening screw sufficiently to eliminate all

end play from the feed roll.

D. Installing Spool Of Wire

CAUTION: Make sure safety glasses are worn when

clipping wire off at the spool or at the end of

the torch - serious eye injury can result due

to the springiness of the wire which quickly

unravels, or a cut wire end which may shoot

across the room.

1. Remove “hairpin” clip from spindle.

2. Position the spool of wire so that when it is placed on

the spindle, wire will be drawn to the feed roll from the

bottom of the spool. The spool should be held so that

the index hole on the back will engage the lug on the

spindle.

3. Slide the spool onto the spindle until it engages the

lug. Lock in place with the hairpin clip.

4. Loosen the brake screw in the center of the spindle

hub, then tighten it just enough to prevent coasting of

the spool when wire is drawn from it. Too much

pressure will load the wire feed motor unnecessarily.

Too little pressure will permit the spool to over-run,

causing the wire to kink and tangle.

5. Thread the wire on to the accessory support assem-

bly as described in E, following.

6. When wire coils are to be used instead of spools,

mount wire reel on spindle as through it were a spool

(see 1 and 3 above). Remove thumbnuts and cover

plate from reel. Remove coil from its package, but do

not remove its binding wires. Slide coil onto reel so

that wire will be drawn from bottom of coil (starting

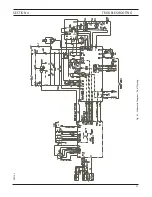

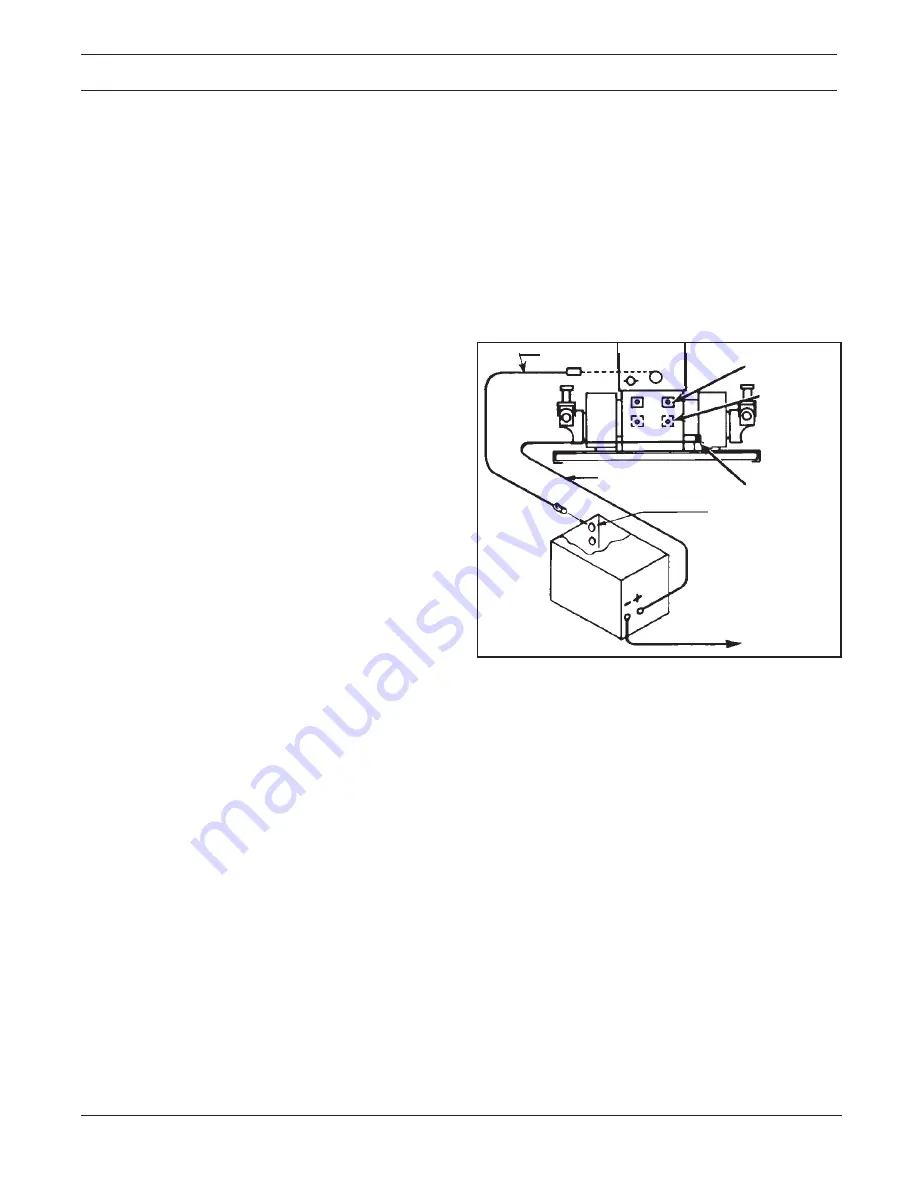

J2

J1

TYPICAL POWER

SOURCE HOOKUP

† ESAB will not honor the warranty on Digimigs that are used with non-

ESAB manufactured interconnect cables and sustain damage that

in ESAB’s opinion is caused by these cables. For a listing of the

proper J1 cables available refer to Section 1.4.

* 4/0 welding cables (customer supplied) are set-up for DCRP (NEG.

TO WORK) operation.

Fig. 2-2. Welding and Control Interconnection Diagram

1. Round off the free end of the welding wire with a file.

2. Release the clapper and unscrew the pressure ad-

justing knob until the pressure spring is free.

3. Thread the wire through the inlet and outlet guides of

the accessory support, and 3 or 4 inches into the

torch conduit.

4. Engage the clapper making sure the wire is held in

the feed roll groove.

5. Tighten the pressure adjusting knob until the wire is

firmly against the feed roll - do not overtighten. The

spring pressure applied should be the minimum

required to provide positive, nonslip wire feed. Too

little pressure will result in wire slippage while exces-

sive pressure will scar and deform the wire. Further

end for a coil is always the outer end). Replace reel

cover plate and thumbnuts. Cut off coil tie wires and

any kinked wire. Then adjust brakescrew and thread

wire to torch as covered in 4 and 5 above.

E. Adjusting The Accessory Support Assembly (See

Fig. 6-5).

When a new wire size or type is to be used, set the

pressure roll adjustment as follows:

SECTION 2

INSTALLATION

TO WORK*

RECPT.

4/0 WELDING CABLE*

OPT. WATER

ADAPTOR

POWER CABLE

ADAPTOR

J1 CABLE †

GSV'S

Содержание Digimig Dual

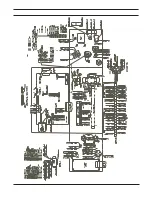

Страница 21: ...21 SECTION 4 TROUBLESHOOTING Fig 4 1 Schematic Diagram Dual Digimig 30914 L ...

Страница 22: ......

Страница 29: ...29 NOTES ...

Страница 30: ...30 NOTES ...