6

The magnetic element is permanently magnetic and

incorporates highly oriented Erium 25 (Ceramic VIII)

magnet material. It requires no external power source.

AC power requirements for the drive motor

are stipulated on the nameplate fixed to the

motor housing.

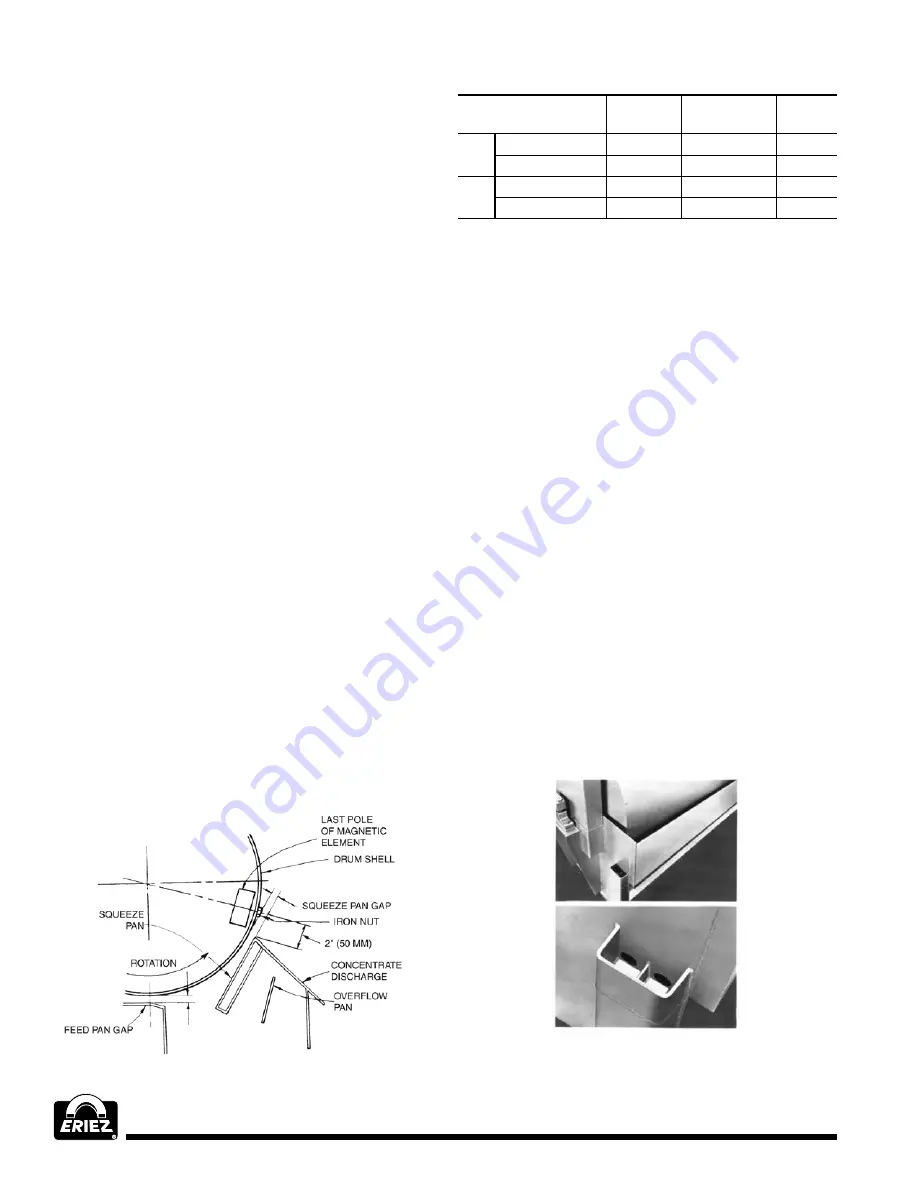

MAGNET ADJUSTMENT

For initial operation or after replacement of parts in

the drum and hub, the magnet position should be

checked. If adjustment of the magnet is required

the following procedure should be followed:

Loosen both shaft clamps. On the end of the shaft

opposite the drive motor, a hole is provided for

adjustment of the magnet with the use of a 1-1/4"

(32 mm) diameter bar. The colored area on the end

of the shaft indicates the approximate position of the

magnetic area. Using this as a guide, slide a small

iron nut across the drum surface until it is attracted

and held by the trailing edge of the magnet. Once you

have done this, adjust the position of the magnet until

the iron nut is approximately 2" (50 mm) above the

discharge lip. Making sure the magnet is held in place,

tighten the shaft clamps (See Figure 3).

The magnet setting as described above should result

in a satisfactory point of discharge; however, slight

adjustment up or down can be made from the normal

position to obtain optimum results. In which the

magnitite is in the horizontal plain (stick outward)

at the discharge lip.

Operation

FIGURE 3

Model

HMDA

Self-Leveling

CL1

36" ø

Feed Pan Gap

1-1/4" (32)

1-1/2" (38)

2" (51)

Squeeze Pan Gap

1-1/4" (32)

1" (25)

2" (51)

48" ø

Feed Pan Gap

1-1/4" (32)

1-3/4" (44)

2" (51)

Squeeze Pan Gap

1-1/4" (32)

2" (51)

2" (51)

FEED AND SQUEEZE‑PAN ADJUSTMENT

Feed and squeeze-pan clearances are set at the

factory, but are adjustable by moving the drum

horizontally or vertically as required. Slotted shaft

clamp mounting holes provide room for lateral

movement and vertical adjustment is accomplished

by adding or removing shims beneath the shaft

and frame.

WATER LEVEL AND OVERFLOW ADJUSTMENT

It is very important in this type of separator to

maintain the proper water level. Overflow volume

should be from 40% to 50% of total tailings flow.

This is controlled by the size of the tailings discharge

openings and the volume of feed. Since the feed

should be constant, adjustment is made by changing

the size of the tailings reducer bushings. Restricting

the openings will increase overflow and vice versa.

An external water level overflow weir is provided

on HMDA Models. A proper water level can be

maintained when water is overflowing the weir

located between the holes in the tank side plate

(See Figure 4).

FIGURE 4