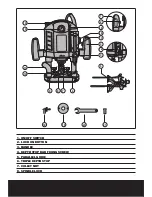

Fig 2

OPERATION INSTRUCTIONS

Warning!

Before using this tool, make sure

you read the instructions carefully.

Note:

Make sure to disconnect the router from

mains supply before fixing any accessories.

1.FITTING THE VACUUM ADAPTOR

(fig2)

For the sake of your health and working

environment, always use a vacuum adaptor.

Use the three screws to fasten the adaptor socket

securely to the routing base. The adaptor socket is

suitable for vacuum clearer with a suction hose of

36mm diameter.

2. FITTING THE ROUTER BIT

To insert a router bit, proceed as follows:

-Loosen the collet nut using the spanner provided

press in the spindle lock button and insert the

required router bit. See Fig3.

-Press in the spindle lock and tighten the collet

nut, making sure at least 3mm protrudes from

the end of the shank. See Fig4. Refer to the

manufacturers instructions for your router bit,

where this gap will be defined as the Maximum

Free Shank Length.

The unit is provided with a 1/4’’ collet. Simply

remove the 1/2’’ collet from the spindle and

replace with the 1/4’’collet.

Please see further safety notes on router cutters

at back of this booklet.

3. ADJUSTING DEPTH OF CUT

The depth of cut is the distance between the triple

depth stop and the length stop bar.

Router bits vary in depth, the triple depth stop

allows for this with its three positions. Use one of

the two following methods:

Method 1: Using a piece of wood method

Fit the router bit, loosen the depth stop bar fixing

screw, Lossen the plunge lock lever (Fig6) and

plunge the router down until it comes into contact

with the workpiece.

Lock the router into this position by pushing down

the plunge lock lever.

Lift up the depth stop bar and insert a piece of

wood the same thickness as the depth of cut

between the stop bar and triple stop bar. See Fig7

and Fig8.Tighten the depth stop bar fixing screw

and release the plunge lock lever to return the

Fig 3

Fig 4

Fig 5

3m

m

Содержание ERB210C

Страница 1: ...ROUTER ERB210C WARRANTY YEARS ...

Страница 2: ......

Страница 18: ......

Страница 19: ...ROUTER ...

Страница 20: ......