�

�

�

��������������������

�

��

�

��

�

��

�

�

�

��������������������

�

��

�

��

�

��

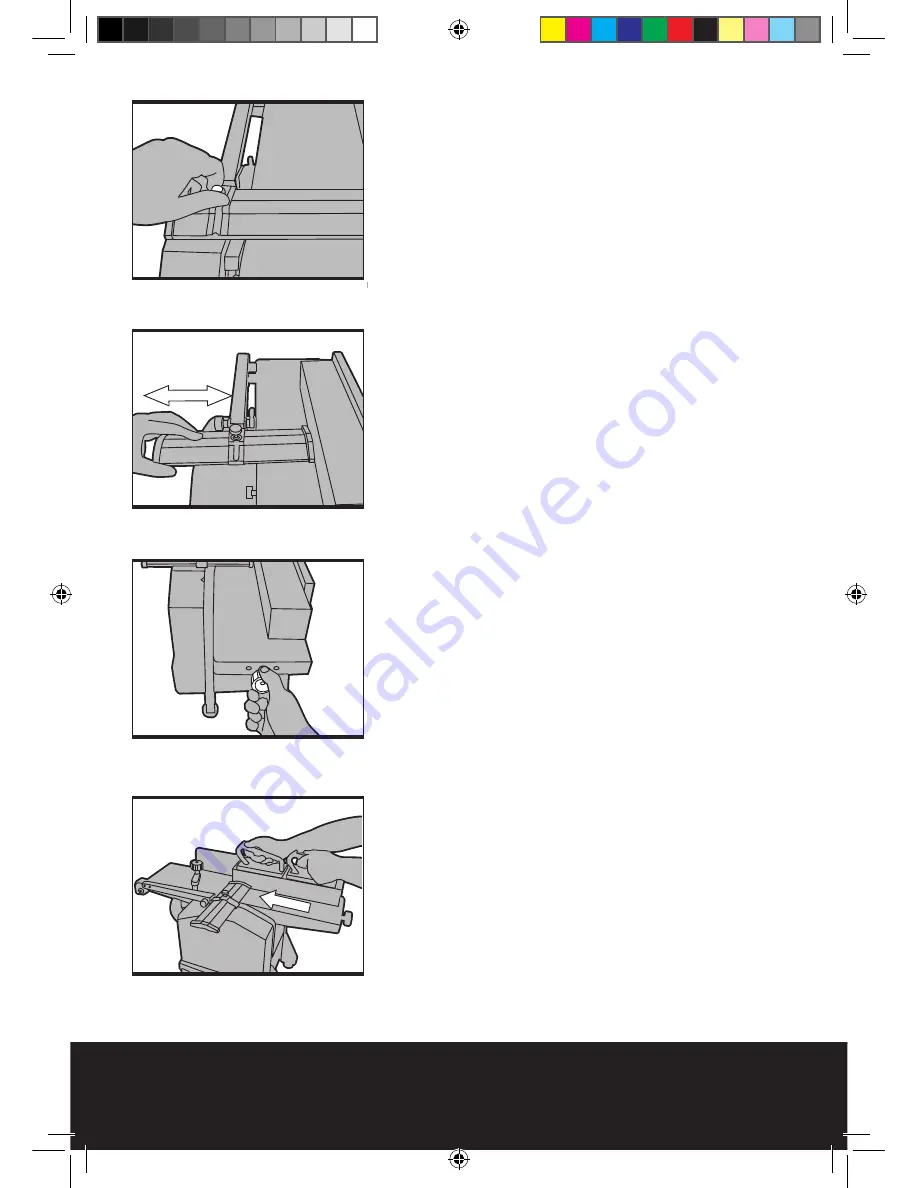

1.3 Setting the blade guard (9). (See Fig 18-

19)

1) Loosen the blade guard locking knob (10).

2) Pull back the blade guard (9).

3) Set the workpiece against the guide fence (8).

4) Slide the blade guard (8) towards the workpiece

(leaving a small gap of a few millimetres).

5) Re-tighten the blade guard locking knob (10) to

secure.

Caution:

When the machine is not in use the

plug should be removed from the mains socket

and the blade guard (9) should be set so that it

covers the whole of the cutter assembly so as to

reduce the risk of injury.

1.4 Setting the depth of cut. (See Fig 20)

The depth of cut is the amount of material

removed from the workpiece with a single pass

over the cutter-block. It is set by the in-feed table

moving up / down in relation to the out-feed table

(this is fixed).

Note:

The maximum cut of 3mm should only be

utilized on softer woods. The planer thicknesser

will give a much better quality finish on harder

woods such as oak if less material is removed on

each pass.

1) Turn the cut depth control knob (5) clockwise

to reduce the depth of cut and anti-clockwise to

increase the depth of cut.

2) The scale to the left of the in-feed table shows

the amount of material that will be removed per

pass.

3) 1 relates to approximately 1mm, 2 relates to

approximately 2mm etc.

1.5. Planing mode: Making a pass with the

workpiece. (See Fig 21)

Once everything is set as needed the planer

thicknesser can now be safely operated.

1) Ensure that the cutter block is free from foreign

objects (including the workpiece to be planed).

2) Connect the planer thicknesser to the mains

supply.

3) Turn the planer on with the green “1” button

(1).

4) Allow the planer to reach its maximum speed.

5) Place the workpiece onto the in-feed table and

ensure that the workpiece stays parallel with the

in-feed table for the whole pass.

6) Slowly push the workpiece forward (over the

Fig 19

Fig 18

Fig 20

Fig 21

BTP210F-M-070928.indd 16

2007-9-28 13:35:57