SC-T7000 series/SC-T5000 series/SC-T3000 series

Revision B

ADJUSTMENT

Overview

212

Confidential

CR related

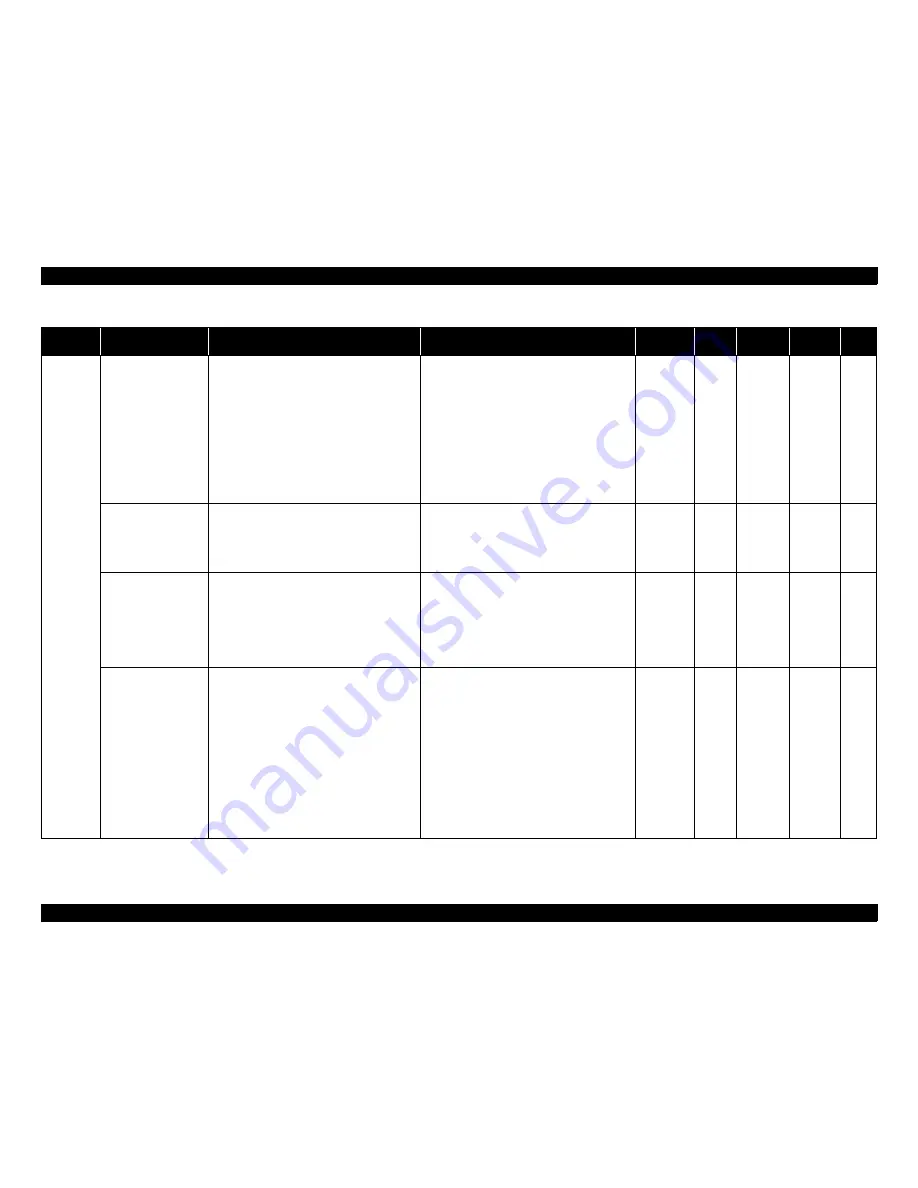

CR Motor Measurement

& Automatic

Adjustment

The CR MOTOR is designed to stop when the

amount of heat generation (motor temperature)

during motor operation reaches a predetermined

limit. The amount of heat generation is estimated

based on the electrical characteristics of the

motor, which vary by motor and power supply of

the printer. Therefore, to get the motor control to

work properly, the electrical characteristics

values of the motor need to be measured and

stored in the memory on the MAIN BOARD.

If this adjustment is not made, the estimation of

the motor temperature cannot be made properly

and may cause the following symptoms.

Even though there is no problem with the

motor temperature, the printer pauses during

printing because it judges that the motor is in

high-temperature state.

Despite the motor is in a high-temperature

state, a lower motor temperature is estimated

and the printer does not stop. This may cause

the printer to malfunction.

Normal

mode

√

p. 279

Auto Uni-d adjustment

Reduces misalignment of ink droplets fired to

paper during unidirectional printing.

If this adjustment is not made, print quality

problems such as misaligned lines, grainy image,

banding may occur.

Normal

mode

√

Premium

Glossy

Photo

Paper

(250)

p. 241

Auto Bi-D adjustment,

acceleration and

deceleration correction

Auto Bi-d adjustment: Reduces misalignment

of ink droplets fired to paper during

bidirectional printing.

Acceleration and deceleration correction: To

improve print quality for bidirectional

printing, corrects the movement speed of the

CR UNIT.

Auto Bi-d adjustment: If this adjustment is not

made, print quality problems such as

misaligned lines, grainy image, banding may

occur.

If this adjustment is not made, print quality

problems may occur.

Normal

mode

√

Premium

Glossy

Photo

Paper

(250)

p. 242

PW + T&B&S check

and adjustment

PW: Checks that the PW sensor detects the

edges of paper correctly. Feed A4 matte paper

from the paper cassette and perform the

detection operation using the Service

Program.

T&B&S: Adjusts the print start position of the

top, bottom, right and left edges of paper.

Feed A4 matte paper from the paper cassette

and print the adjustment patterns using the

Service Program. Measure the adjustment

patterns then input the measurement result.

The print start position is automatically

adjusted.

If this adjustment is not made, the width or length

of paper cannot be detected correctly. As the

result, misaligned print position or insufficient

blank space may occur, or printed images may be

broken.

Normal

mode

√

Archival

Matte

Paper/

Enhanced

Matte

Paper

p. 243

Table 4-2. Adjustment Items

Class

Adjustment Items

Overview

Symptoms that the Adjustment is Needed

Printer Mode

Service

Program

Jig

Media

Page

Содержание SC-T3000

Страница 10: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Страница 39: ...Confidential C H A P T E R 2 TROUBLESHOOTING ...

Страница 66: ...Confidential C H A P T E R 3 DISASSEMBLY ASSEMBLY ...

Страница 197: ...Confidential C H A P T E R 4 ADJUSTMENT ...

Страница 280: ...Confidential C H A P T E R 5 MAINTENANCE ...

Страница 290: ...Confidential C H A P T E R 6 APPENDIX ...

Страница 309: ...SC T7000 series SC T5000 series SC T3000 series Revision B APPENDIX Panel Menu Map 309 Confidential 6 3 Panel Menu Map ...