M200 / M205 / M100 / M105 Series

Revision A

Confidential

Troubleshooting

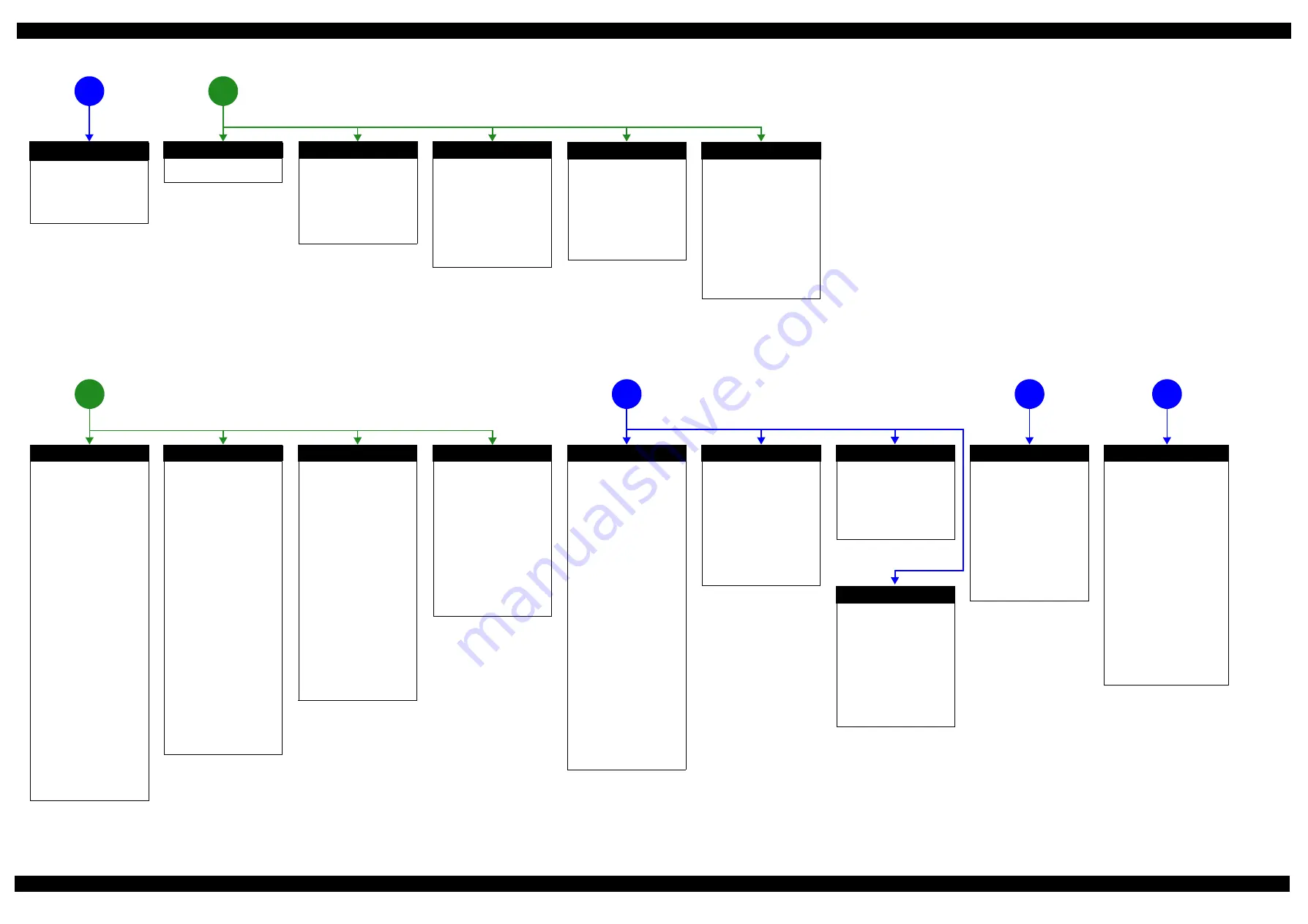

Troubleshooting Workflow

11

Figure 0-1. Troubleshooting Workflow (2)

Fatal error

Please refer to

Maintenance error

[Occurrence Condition]

This error occurs when

maintenance counter in EEPROM

exceeds the specified value.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

[Troubleshooting]

• Porous Pad replacement &

Maintenance counter reset

Ink End error

[Occurrence Condition]

This error occurs when ink in Ink

Cartridge is empty.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

[Troubleshooting]

• Refill ink and reset ink counter

by panel.

Paper Jam Fatal error

[Occurrence Condition]

This error occurs when CR Unit is

blocked by jammed paper.

[Major Occurrence Timing]

• Power-on timing

[Major Troubleshooting]

• Remove jammed paper

※

On this product, if CR Unit

touches jammed paper, CR Unit

moves back in the opposite

direction so that customer can

remove the paper. However, if CR

Unit cannot move in this

sequence, this error occurs.

Paper Jam error

[Occurrence Condition]

This error occurs when top/

bottom of paper is not detected by

PE Sensor in the specified steps of

paper loading / ejecting operation

correctly.

[Major Occurrence Timing]

• Power-on timing

• Paper loading timing

• Paper eject timing

[Major Troubleshooting]

1 Perform paper eject operation

from operation panel.

• Success

Starts paper feeding

operation again if printer has

print data.

• Fail

Occurs paper jam error

again.

2 If fail in the above 1, remove

the paper by opening Scanner

Unit.

3 Perform paper eject operation

from operation panel again.

• Success

Starts paper feeding

operation again if printer has

print data.

• Fail

Occurs paper jam error

again.

4 Check the following if failed in

Step 3.

• Foreign object

• Detached parts

• PE Sensor Lever

• PE Sensor

• Porous Pad on Paper Guide

Front

• Main board

No Paper error

[Occurrence Condition]

This error occurs when top of

paper can not be detected

correctly by PE Sensor in the

specified steps up to completion

of the paper loading operation.

(No paper / No loading / large

paper skew)

[Major Occurrence Timing]

• Paper loading timing

[Major Troubleshooting]

1 Set paper in ASF and perform

paper feed operation.

2 If the paper stops before

reaching PE Sensor, remove it

and check the paper condition.

3 A)If paper is OK, set paper in

ASF and move edge guides to

appropriate position, and

perform 2 again.

B)If damage in the above 2,

check foreign materials / parts

come-off / parts transformation

in paper path.

4 If the problem is not solved by

3-A) & 3-B), check the

following.

• Foreign object

• Detached parts

• Surface condition of LD

Roller or PF Roller

• PE Sensor Lever

• PE Sensor

• Main Board

• PF Motor

Double Feed error

[Occurrence Condition]

When manual duplex printing is

selected using the printer driver,

this error occurs if the actual

paper length detected by PE

Sensor does not match with the

paper length specified in the

printer driver. (The error occurs

when the actual length is longer

than the theoretical length

specified in the driver.)

[Major Occurrence Timing]

• Paper loading timing

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

(Main Board replacement)

• Main Board replacement

※

This error may occur in the

manual duplex printing if the

inverted sheet printed on the first

side sticks to the second sheet

when the first side printing is

complete and the sheet is inverted

and set to ASF to print on the

other side.

No Power

*

[Presumable Cause]

• PS Unit damage

• Main Board damage

[Major Troubleshooting]

• PS Unit replacement

• Main Board replacement

Poor Printing

[Phenomenon]

• Poor printing quality

• Ink stain on paper

• Dot missing

• Paper eject without printing

[Presumable Cause]

• Driver / Panel mis-setting

• Contamination of CR scale

• Contamination of Printhead

cover

• Printhead damage

• Ink clogging of Printhead

• Contamination on Cap Unit /

Wiper of Ink System Assy

• Ink System Assy damage

• Float of Porous Pad on Paper

Guide Front

• Narrower/Wider PG

(out of standard)

• PE Sensor Lever damage

• PE Sensor damage

• Ink tank ventilation film gets

wet.

[Major Troubleshooting]

• Driver / Panel re-setting

• CR Scale replacement

• Printhead cover cleaning

• Printhead cleaning

• Printhead replacement

• Rubber cleaning of Cap Unit

• Ink System Assy replacement

• Porous Pad re-installation

• Printer replacement

• PE Sensor Lever replacement

• PE Sensor replacement

(Main Board replacement)

• Ink tank replacement

Poor Paper Loading

[Presumable Cause]

• Use of 3rd party media

• Edge guide mis-setting

• Foreign material

• Part come-off

• Contamination of LD Roller or

PF roller

[Major Troubleshooting]

• Recommendation of EPSON

media

• Edge guide re-setting

• Foreign material removal

• Part re-installation

• Roller replacement

Abnormal Noise

[Presumable Cause]

• Foreign material

• Insufficient grease

• Gear damage

[Major Troubleshooting]

• Foreign material removal

• Lubrication of grease

• Gear replacement

Scanner failure

[Presumable Cause]

• Contamination of Scanner

Glass

• Contamination of Document

Pad

• CIS Unit bonding failure

• CIS Unit damage

• Scanner Motor damage

• Insufficient grease

[Major Troubleshooting]

• Scanner Glass cleaning

• Document Pad cleaning

• Document Pad replacement

• CIS Unit replacement

• Scanner Motor replacement

• Lubrication of grease

2

*:

If the printer can turn on but turns off right away, the protection

circuit may cut off the power due to an error such as a circuit

failure.

The power-on sequence

does not start

Paper Size Unmatch error

[Occurrence Condition]

This error occurs if the actual

paper length detected by PE

Sensor does not match with the

paper length specified in the

printer driver. (The error occurs

no matter when the actual length

is longer or shorter than the

theoretical length specified in the

driver.)

[Major Occurrence Timing]

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

(Main Board replacement)

• Main Board replacement

3

ADF Unit failure

[Phenomenon]

• Paper is not fed

• Multi-feed

• Paper jam

• Skewed document

[Presumable Cause]

• Deterioration of Pickup Roller

• Deterioration of ADF Pad Assy

• Damage to gears

• Damage to Scanner Motor

• Contamination on document

glass

• Foreign object

• Damage to ADF Paper Guide

Cover Assy

• Deterioration of Paper Eject

Roller

• Scanner Carriage

failure

[Major Troubleshooting]

• Replace ADF Paper Guide Cover

Assy

• Replace ADF Pad Assy

• Clean document glass

• Remove foreign material

• Replace ADF Unit

• Replace Scanner Unit

1

Error is indicated during power-on

sequence

Error is indicated during printing nozzle check pattern.

4

5

6

Problems related to print result or during printing

Scanning cannot

be performed

successfully

ADF does not

operate normally

Incomplete Initial Ink Charge

[Occurrence Condition]

Ink LED is ON and STM

indicates "Initial ink charging is

not complete".

[Major Occurrence Timing]

• Print start timing

[Troubleshooting]

• Perform initial ink charge

Blank printing

[Phenomenon]

• Blank printing

[Presumable Cause]

• Valve closes

• Ink tank ventilation film gets

wet

• Ink tube crumples

• Ink tube connection is

incomplete

[Major Troubleshooting]

• Open valve

• Ink tank replacement

• Ink tube re-installation

Содержание M200

Страница 1: ...SERVICE MANUAL CONFIDENTIAL Color Inkjet Printer M200 M201 M205 M100 M101 M105 SEMF12 012 ...

Страница 6: ...Confidential Revision Status Revision Date of Issue Description A October 17 2012 First Release ...

Страница 9: ...Confidential CHAPTER 1 TROUBLESHOOTING ...

Страница 18: ...Confidential CHAPTER 2 DISASSEMBLY REASSEMBLY ...

Страница 59: ...Confidential CHAPTER 3 ADJUSTMENT ...

Страница 73: ...Confidential CHAPTER 4 MAINTENANCE ...

Страница 80: ...Confidential CHAPTER 5 APPENDIX ...