EX-5100 C

OMBUSTIBLE

ENMET

3

3.0 Installation of the EX-5100

C

AUTION

:

Area must be declassified during installation.

The

ENMET

EX-5100

gas sensor/transmitter (S/T) is a 3-wire, 24

V

DC

4-20 mA S/T for the detection of combustible gas. The

S/T is meant to be used in conjunction with an appropriate power supply and controller. The

ENMET

EX-5100

sensor/transmitter is in an enclosure rated for use in a Class I, Div. 1, Groups B, C, D, classified area. Appropriate wiring,

conduit and fittings are required for proper installation in a explosion proof rated environment.

C

AUTION

:

Since the sensor/transmitter detects gas only at the sensor location, pay attention to the possible sources of gas, the

density of the gas, locations where the gas may be confined and locations where the gas may damage or injure

property or personnel, when choosing locations of sensor/transmitters.

Take into consideration environmental factors when deciding on S/T location. Avoid locations where the S/T may be damaged

by liquid immersion, excessive heat or other know hazards. Also, take precautions to insure condensation inside of the conduit

does not enter the S/T.

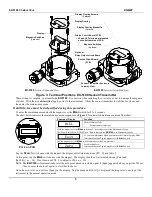

3.1 Mounting the EX-5100 Enclosure

Mount the enclosure, using the two mounting holes provided see Figure 2. Pay particular attention to the source and density of

the gas being detected when choosing the location. Mount the S/T near the ceiling for lighter than air gases /vapors and near

the floor for heavier then air gas/vapors. Contact

ENMET

if you have questions regarding your application.

C

AUTION

:

Before connecting S/T to controller remove the power source to controller. Failure to do so may cause damage to

sensitive components.

Menu

Select

Figure 2: EX-5100 Mounting Dimensions

Optional

Conduit fitting

Typically: ½

″

NPT female

Mounting Holes

2 places, 0.313

″

T

OP

V

IEW

Sensor

Sensor/Transmitter

Enclosure Top View

Sensor/Transmitter

Enclosure Side View

Sensor

S

IDE

V

IEW

½

″

NPT female