13

010.4150.0720 08.21

Freeze protection concerns: During a system shutdown

where combustion halts for an extended period of time

(other than normal cycling), cold air will travel back down the

stack and exhaust breechings, through the economizer and

into the combustion source. If the cold air is below freezing,

it could freeze the plates and cause a rupture, ultimately

destroying the economizer. For potential freezing applications

where the water flow might stop, a manual system shut

down routine should be incorporated. It is not recommended

to use solenoid type drain valves for auto draining in subzero

environments unless absolutely necessary.

Do not insulate the economizer where factory insulation has

already been applied or damage to the exchanger can occur.

Insulate piping and exhaust ducting as required.

Ensure that no liquid connections interfere with the opening

of recovery unit trays. Economizer relief valves shall not have

set pressure ratings higher than the rated pressure of the

heat modules. Liquid storage tank relief valves shall not have

discharge pressure ratings higher than the rated pressure of

the storage tank. To avoid safety valve leakage, ensure that

safety valve set pressure is sufficiently higher than dead head

pressure of the feed pump.

It is recommended that the pipe and circulating tank (if

included) be insulated to reduce heat loss.

If existing conditions may subject the heat modules to

internal scale build up, pressure gauges (furnished by others)

should be installed on the liquid inlet and outlet sides of

the economizer. This will enable monitoring of liquid flow

restriction. Capped tees, one on the liquid inlet side and

one on the liquid outlet side, incorporated into the piping

installation may allow a descaling solution to be used with

the economizer in place. Consult the factory for suitable

descaling solutions.

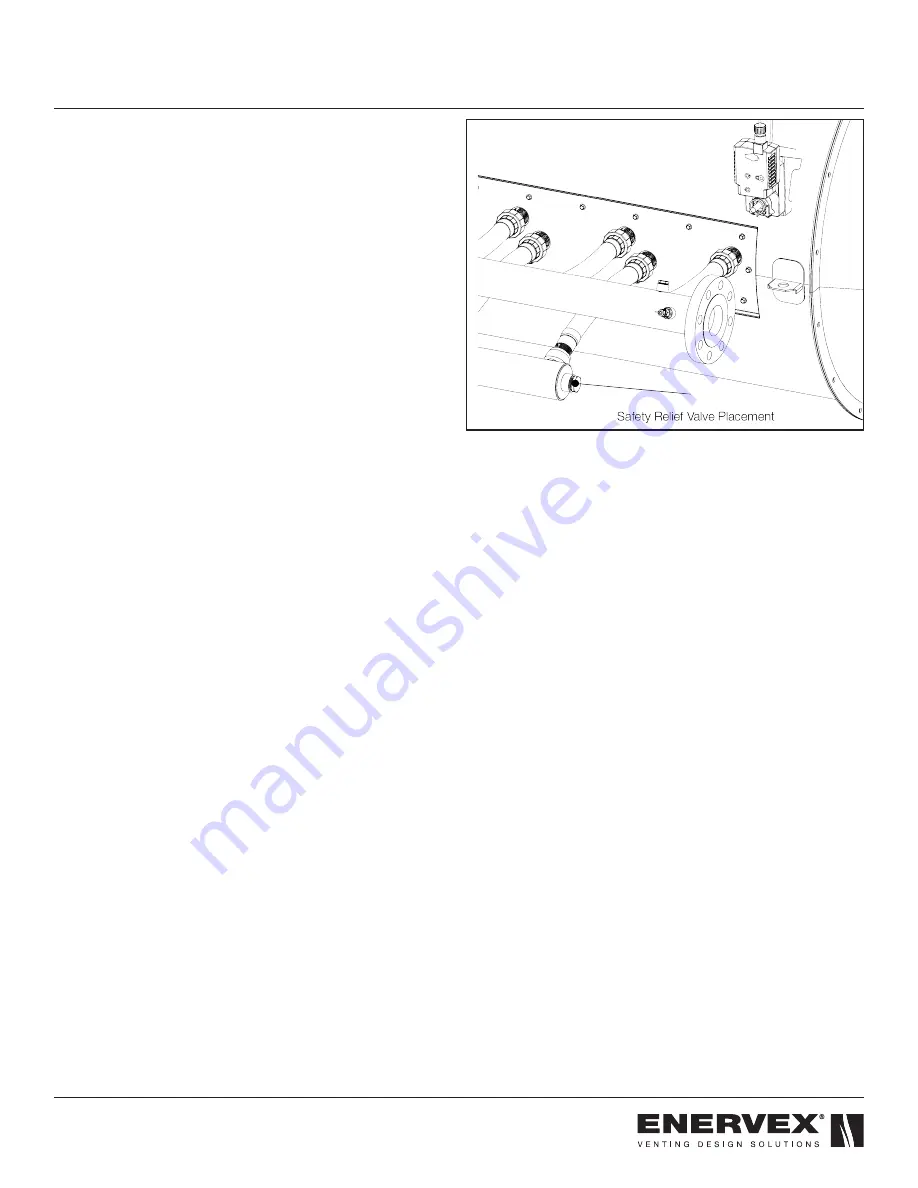

Fig 13