17

www.uniquip.ca

!

Maintenance Procedures cont’d ...

2.Lubrication

Schedule

Regularly scheduled lubrication of the drive chain, gear box, rear wheels, tines & rotor assembly, and linkage

joints in the carriage is essential to smooth performance and extended equipment life. The following schedule is

a recommended guide to lubricating your ENAR24HC. The schedule should be adjusted for various

environmental conditions and frequency of use.

Item

Suggested Lubricant

Every 20

hours

Every 60

hours

As

required

After each

pressure

wash

Storage

Engine

Refer to Owner’s Manual

for Engine

Gear Box

SAE80W90

Wheels

Lithium-based Grease

Drive Chain

Spray-on Graphite

Dry Lubricant

Coring Tines

Mineral-based Rust

Inhibiting Oil

Linkage

30W Oil

Zerks

Lithium-based Grease

C.General Service Procedures

The following are general guidelines for servicing common wear components on the ENAR24HC Aerator.

ALL MAIN-

TENANCE AND SERVICE WORK MUST BE PERFORMED BY A TRAINED AND EXPERIENCED TECHNICIAN

.

Ensure that the work area is clean and free of debris prior to starting any maintenance or service work. Small particles may

become trapped in key components that may lead to serious damage to the machine and cause severe bodily harm to the

operator or technician.

Before performing any service and maintenance procedures, consult these general safety procedures for a safe working

environment.

1.Make sure that both the engine and aerator are cool prior to any service or maintenance work.

2.Verify that work area is clean and free of any debris, tripping or fi re hazards, and other

potential sources of danger.

3.Always wear proper safety clothing and equipment for the job. These can and should include

eye and ear protection, protective helmets, gloves, dust mask and any other items that are

appropriate for the job and jobsite requirements

4.Ensure that the technician has tied back or remove any loose hair, clothing and any other

potential hazards and obstructions

5.Disconnect spark plug.

6.Remove both weights and refasten safety latch.

Technician should read and thoroughly understand all manuals pertain-

ing to the machine to be serviced. Do NOT proceed with any service and

maintenance activity until ALL questions and concerns have been addressed.

Please call Uniquip Canada at 1-888-332-4012 for technical support and

advice.

!

ALWAYS consult and verify that all local codes and bylaws are followed

before performing any service or maintenance procedures.

Содержание ENAR24HC

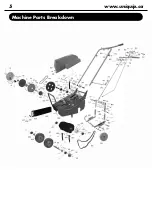

Страница 10: ...5 www uniquip ca Machine Parts Breakdown...

Страница 27: ...22 www uniquip ca Notes...