Installation Instructions

Installation

Scope of Application:

petroleum Fats, Oil and Grease as a by-product of commercial foodservice activities. The Endura® XL interceptor models are

tested and rated.

Accessibility:

Installations shall be made in such a manner that full access for maintenance and cleaning is maintained once the interceptor is

commissioned. A zone based on a column measured 3ft out from the cover perimeter and extending 7ft vertically is recommended.

Inlet (IN) and Outlet (OUT) connections are indicated on the interceptor itself. Ensure that the interceptor is in the correct

Location:

the source and the interceptor. Adequate provision for rodding and service access is particularly important upstream of the

interceptor. Please refer to local code requirements.

Drain lines servicing the interceptor shall be laid at a minimum ¼”per foot fall and with more gradient where possible.

Piping Connections:

The primary bulkhead-style connections (in-line) of Endura® XL are injection molded in Polyproylene (PP). PP does not accept

solvent weld cement and will not provide a serviceable connection. DO NOT SOLVENT WELD these drain connections.

Best practice and most codes typically require the use of Nationally or locally approved Mechanical Joint (MJ) couplings for the

Flow Control:

to meet the requirements of PDI G-101, assuming that the applicable venting and installation criterial are met (See Page 12).

Trapping:

equivalent, in compliance with applicable plumbing code requirements.

Venting:

The installation of the interceptor shall be vented downstream in accordance with local code requirements - typically within 10 ft max.

• Air Gap/ Air Break

• Flow Control Device

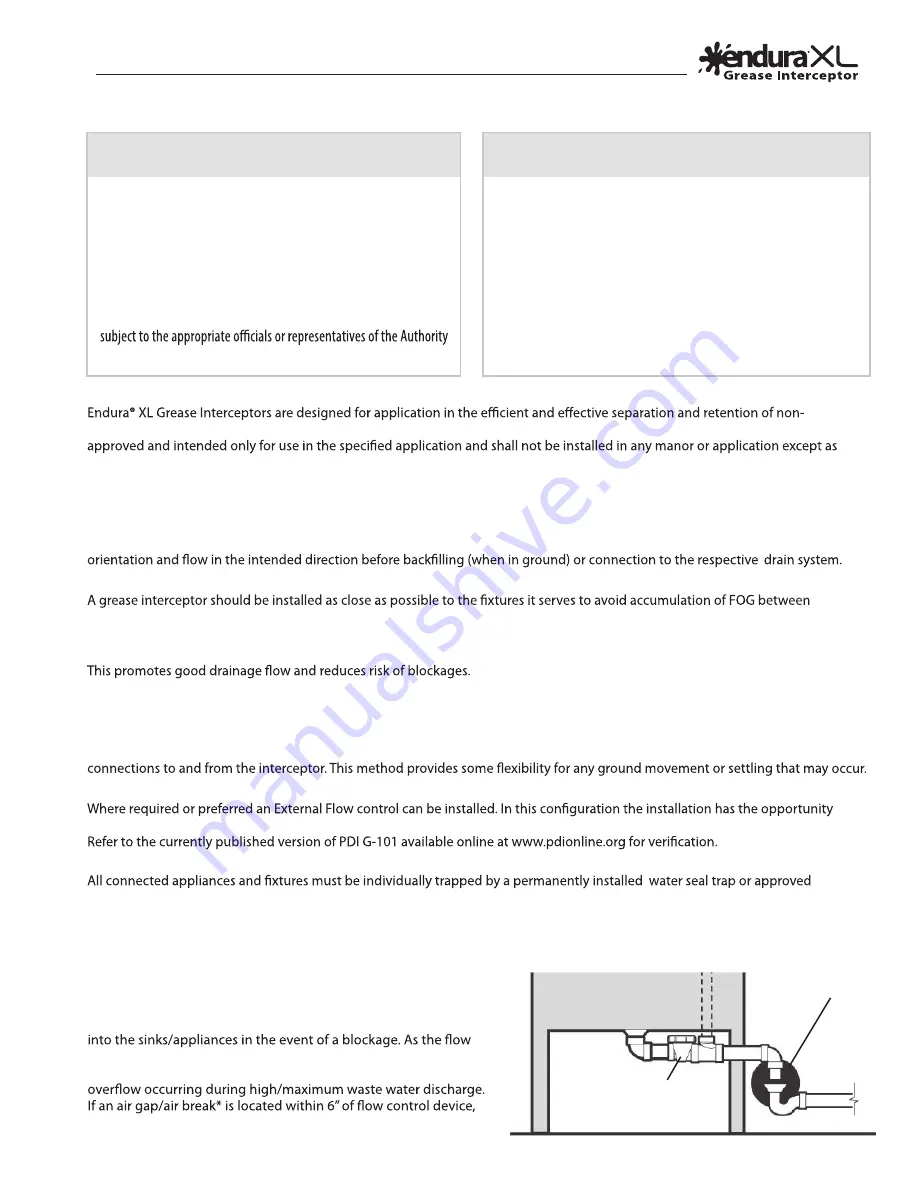

Indirect Connections/ Air Gap/Air Brake :

Some local jurisdictions require warewashing installations to be

made on an indirect basis incorporating an air gap.

This is to prevent the back up of contaminated waste water

control device provides a restriction within the system it must be

incorporated before the indirect connection to prevent the risk of

installation of the air intake tee is optimal.

*Dependent on jurisdiction

WARNING – SAFETY FIRST!

GREASE INTERCEPTORS ARE HAZARDOUS

ENVIRONMENTS AND MUST NEVER BE LEFT UNCOVERED

AND UNATTENDED, EVEN DURING MAINTENANCE.

• All access covers MUST be fully and completely secured

• All required bolts MUST at all times be in place and well tightened

• Missing bolts MUST be reported to management and replaced immediately

•

•

Covers MUST meet the required load rating for the application (see the

Technical Information section)

Do NOT use alternate covers

WARNING – SAFETY FIRST!

ALL INSTALLATION SHALL BE CONDUCTED UNDER THE

APPLICABLE HEALTH AND SAFETY REGULATIONS IN

FORCE WITHIN THAT JURISDICTION.

Plumbing operatives shall be adequately trained and appropriately

licensed to conduct the installation. All installations will be made

respective and in compliance with applicable plumbing code and any

locally published by-laws. Installation and approval of the same is

Having Jurisdiction (AHJ).

- 11 -