SAFETY INFORMATION FOR USERS OF LP-GAS

Someday when there may not be a minute to lose,

everyone's safety will depend on knowing exactly what to

do. If, after reading the following information, you feel you

still need more information, please contact your gas

supplier.

•

•

Use your neighbor's phone and call a trained LP-Gas service

person and the fire department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not re-

enter the building or area.

Finally, let the service man and firefighters check for

escaped gas. Have them air out the area before you return.

Properly trained LP-Gas service people should repair the

leak, then check and relight the gas appliance for you.

have been out of service for a time may develop internal

rust which will cause odor fade. If such conditions are

suspected to exist, a periodic sniff test of the gas is

advisable.

If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the

same immediate action recommended above for the

occasion when you do detect the odorized LP-Gas.

If you experience a complete "gas out," (the container is

under no vapor pressure), turn the tank valve off

immediately. If the container valve is left on, the container

may draw in some air through openings such as pilot light

orifices. If this occurs, some new internal rusting could

occur. If the valve is left open, then treat the container as a

new tank. Always be sure your container is under vapor

pressure by turning it off at the container before it goes

completely empty or having it refilled before it is

completely empty.

If you have any question about the gas odor,

call your LP-gas dealer. A periodic sniff test of the LP-

gas is a good safety measure under any condition.

•

•

odorant. Odorants in LP-Gas also are subject to oxidation.

This fading can occur if there is rust inside the storage tank or

in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into

walls, masonry and other materials and fabrics in a room. That

will take some of the odorant out of the gas, reducing its odor

intensity.

LP-Gas may stratify in a closed area, and the odor intensity

could vary at different levels. Since it is heavier than air, there

may be more odor at lower levels. Always be sensitive to the

slightest gas odor. If you detect any odor, treat it as a serious

leak. Immediately go into action as instructed earlier.

Propane (LP-Gas) is a flammable gas which can cause fires

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety pre-

cautions which can protect both you and your family from

an accident. Read them carefully now, then review them

point by point with the members of your household.

•

•

•

•

Do not operate electric switches, light matches, use your

phone. Do not do anything that could ignite the gas.

Get everyone out of the building or area. Do that

IMMEDIATELY.

Close all gas tank or cylinder supply valves.

LP-Gas is heavier than air and may settle in low areas

such as basements. When you have reason to suspect a

gas leak, keep out of basements and other low areas. Stay

out until firefighters declare them to be safe.

• Learn to recognize the odor of LP-gas.

•

•

•

Your local LP-Gas

Dealer can give you a "Scratch and Sniff" pamphlet. Use it

to find out what the propane odor smells like. If you suspect

that your LP-Gas has a weak or abnormal odor, call your LP-

Gas Dealer.

If you are not qualified, do not light pilot lights, perform

service, or make adjustments to appliances on the LP-Gas

system. If you are qualified, consciously think about the

odor of LP-Gas prior to and while lighting pilot lights or

performing service or making adjustments.

Sometimes a basement or a closed-up house has a musty

smell that can cover up the LP-Gas odor. Do not try to light

pilot lights, perform service, or make adjustments in an area

where the conditions are such that you may not detect the

odor if there has been a leak of LP-Gas.

Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people

should be particularly alert and careful when new tanks or

cylinders are placed in service. Odor fade can occur in new

tanks, or reinstalled old tanks, if they are filled and allowed

to set too long before refilling. Cylinders and tanks which

Some people cannot smell well. Some people cannot smell

the odor of the chemical put into the gas. You must find out

if you can smell the odorant in propane.

The odorant in LP-gas is colorless, and it can fade under

some circumstances.

Smoking can

decrease your ability to smell. Being around an odor for a time

can affect your sensitivity or ability to detect that odor.

Sometimes other odors in the area mask the gas odor. People

may not smell the gas odor or their minds are on something

else. Thinking about smelling a gas odor can make it easier to

smell.

For example, if there is an underground

leak, the movement of the gas through soil can filter the

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That's your signal to go into immediate action!

NO ODOR DETECTED - ODOR FADE

SOME POINTS TO REMEMBER

Page 4

MV1XX-1-0603

Содержание MV 120

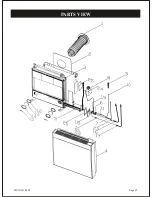

Страница 15: ...Page 15 PARTS VIEW MV1XX 1 0603 ...