Important: remove styrofoam inside front cover now.

Place the foam

pads on the four raised “bumps” on the rear of the unit.

These foam pads will protect the wall surfaces from

damage.

Warning: the heater will not function properly if these

connections are not tight and clean.

Lighting Instructions

Connecting the gas supply

After connecting the gas supply to the gas control on the

heater, the connections must be checked thoroughly for

leaks.

Remove the small piece of wood from the rear of the heater

and discard. Four small adhesive foam pads are included with

the unit and can be found in the accessory bag.

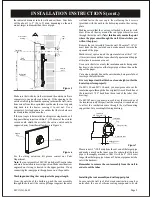

Hang the heater on the arms on the wall support bracket, taking

extreme care to ensure that the small diameter vent pipe fits

inside the smaller opening in the rear of the unit. (See Figure

9). The larger diameter vent pipe must then slide over the

outside flange opening.

Secure the unit to the

wall support bracket with the two screws provided.

Attach the

to the back of the unit so that

they may be read when necessary. These instructions are for

current and future use. Make sure they remain accesible after

the unit is installed.

Connect the gas supply to the 3/8” (9.5 mm) pipe on the lower

part of the right side of the heater by using standard

connectors. Please refer to the cautionary remarks noted in the

beginning of this manual.

With the shut-off valve turned ON, but the gas control

knob on the heater OFF, apply liberal amounts of a soapy water

solution to all of the piping joints. A gas leak will cause

bubbles to form. Note any leaks in the piping system, then shut

off the gas at the shut-off valve, or at the gas meter or

propane/LP tank serving the building. Fix the leaking joint and

re-test the joints as directed above.

Once the supply is checked and does not leak, place the cover

on the unit. See Figure 10. Be sure the foam packing has been

removed. Secure the cover with the two nuts at the bottom of

the unit which you had removed when unpacking.

eventual water filtration or the entrance of bugs is necessary.

Press the flange against the outer wall surface and fasten the

vent cap to the wall using the 4 screws (provided with the unit)

in the holes prepared in the vent cap plate. Once the vent is

secured to the wall, proceed filling the gaps between the vent

plate and the wall with silicone sealing compound.

Inside the building, place the wall support plate (which is

taped inside the cabinet during shipment) over the open end of

the vent pipe and push the plate firmly against the interior wall.

Now level the plate with carpenter level and mark the

mounting holes with a pencil (see Figure 8). Remove the wall

support plate from the vent pipe and drill the two holes with the

appropriate drill bit.

Place the wall support plate over the vent pipe again and affix

the plate to the wall using the two screws provided with the

unit.

You might need to handle the introduction of the larger

pipe into the hole of the support plate with your fingers

since the pipe could have suffered some minor

deformation through the cutting process.

Note: hollow wall fasteners (also supplied with the unit)

are necessary for model MV 120. Models MV 130 and MV

145 can be mounted on the wall studs.

Mounting the furnace

Take off the cover by loosening the two screws at the bottom.

Pull the bottom away from the heater and lift it up off the tabs

on top.

INSTALLATION INSTRUCTIONS (cont.)

Figure 8

Figure 9

Figure 10

Page 10

MV1XX-1-0603

Содержание MV 120

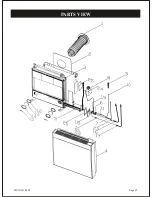

Страница 15: ...Page 15 PARTS VIEW MV1XX 1 0603 ...