12431-10-1008

Page 15

Replacing Fan and Oiling the Motor

The fan motor should be cleaned and oiled once each heating season.

To reach the motor, withdraw the metal shroud surrounding the fan

blade by removing the screws on each side. Oil holes are located

on the top at each end of the motor. Use a few drops of #10 motor

oil. To clean the motor, blow air through its ventilation openings

with a vacuum cleaner or low pressure air source.

If fan motor is replaced, the silicone rubber gaskets, see Page 16,

Index No. 4, Part No. 712059, should also be replaced. The gaskets

must be stretched to fit the motor bolts into the gasket holes and then

the motor and gaskets installed on the motor mounting bars.

GENERAL :

All furnaces have been fire-tested to check for proper

operation. This includes, main burner flame, pilot flame, fan opera-

tion, fan control, limit control and automatic valve operation. If

the furnace fails to function on initial installation, it is advisable

to re-check the following:

1. 115 volts to the junction box.

2. Inlet gas pressure.

3. The 24 volt system.

4. Type of gas being used and that shown on the rating label.

The Service Department at Empire Comfort Systems, Inc. may be

contacted to assist in servicing furnace or call a qualified service-

man..

Servicing the Pilot and Main Burners, Pilot Orifice, Thermo-

couple, and Main Burner Orifices:

Disconnect the gas supply

at the inlet to the control valve. Then remove the burner door to

which the above components are attached.

Servicing The Fan Motor:

The upper front panel, the shroud

surrounding the fan blade and fan blade must be removed. See

"Replacing Fan and Oiling the Motor" paragraph above.

Spark Igniter Does Not Light Pilot:

With air in the gas line, such

as when the furnace is first installed or was off all summer, the

pilot flame may be too lean to ignite on the first few trials. Turn the

control valve knob to pilot position and depress the red reset button.

Holding the button down continually to bleed the line:

1. Use lighter rod to light pilot with a match.

2. Use the piezo ignitor at 30 second intervals until it lights.

If Electrode Does Not Produce Spark:

1. Check wire connections.

2. Check gap for pilot burner to the electrode tip. Should be

between 1/8" and 3/16". Electrode wire and tip must be more

than 1/4" away from all other metal components.

If Pilot Does Not Light By Any Means:

1. Check valve knob for being in the "Pilot" position.

2. Check pilot adjustment for being full open (counterclockwise

to open).

3. If gas is available in the supply tubing, the pilot orifice and/or

pilot burner is probably restricted by a spider web. Clean

pilot assembly and relight.

If Pilot Does Not Remain On After Releasing Knob:

1. Follow instructions and hold button down longer and

harder.

2. Determine if pilot flame extends past thermocouple; if not,

adjust input or clean pilot burner.

3. Replace thermocouple if millivolts read less than 15 mil-

livolts.

Pilot Outage During Normal Operation:

1. Check air inlet tube for a good tight fit at both ends (6"

diameter tube).

2. Check burner door and pilot hole cover for tight seal.

3. Check input by manifold pressure gauge or gas meter.

Main Gas Valve Does Not Open When Thermostat Is Turned

To On:

1. Check for 24 volts to valve by removing one wire and

touching to the

SAME TERMINAL

it was on. Terminal

should have a light spark.

DO NOT SHORT ACROSS

TERMINALS, AS IT WILL BURN OUT THE WALL

THERMOSTAT.

2. Thermostat wires at the wall may be shorted, so check for

a faulty thermostat.

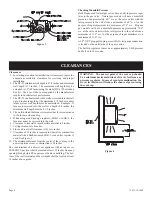

3. To check for line voltage to furnace, remove lower front

panel and switch compartment cover and short across two-

terminal fan control to allow fan to operate. (Figure 13)

SERVICE & MAINTENANCE SUGGESTIONS

Содержание DV-55SPP

Страница 17: ...12431 10 1008 Page 17 PARTS VIEW...

Страница 18: ...12431 10 1008 Page 18 SERVICE NOTES...

Страница 19: ...12431 10 1008 Page 19 SERVICE NOTES...