12431-10-1008

Page 13

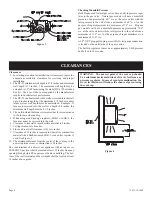

The correct flame will be a short blue inner flame with a much

larger light blue outer flame. The main burner (Figure 12) shows

the approximate height of each part of the flame for each gas. The

burner does not have a primary air adjustment. The flame will be

correct if the factory-set pressure and orifice opening are used. After

the furnace has been operating, the burner ports may be blocked by

foreign matter carried in by combustion air. Therefore, cleaning of

the burner may be needed for proper flame.

To clean burner port disconnect the gas supply to the valve, and

remove the eight screws fastening the burner door. After remov-

ing the burner door from the combustion chamber, remove rear

burner, pilot burner and front burner. With front and rear burners

removed from furnace, force water into the ribbon ports and dry

with air pressure.

The correct pilot flame (Figure 11) will be blue, extending past

the thermocouple. The flame will surround the thermocouple just

below the tip.

Natural gas pilots require adjusting when the inlet gas pressure is

above 5" w.c. Remove the pilot cover screw on the control valve

(Figure 3, page 8), and turn the adjustment screw clockwise to

reduce flame. Replace pilot cover screw to eliminate gas leaking

at that control valve opening.

LP gas (propane) will not require adjustment.

After use, cleaning may be required for the proper flame.

PROPER FLAME ADJUSTMENT

Figure 11

Figure 12

PILOT FLAME CHARACTERISTICS

MAIN BURNER FLAME CHARACTERISTICS

Содержание DV-55SPP

Страница 17: ...12431 10 1008 Page 17 PARTS VIEW...

Страница 18: ...12431 10 1008 Page 18 SERVICE NOTES...

Страница 19: ...12431 10 1008 Page 19 SERVICE NOTES...