32186-0-0513

Page 2

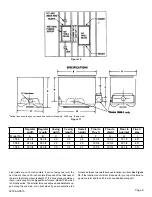

Specifications

Models

3588

5088

7088

Input BTU/HR

32,500

45,000

65,000

dimensions

Register Length & Width

33 3/4" x 22 3/4"

36 3/4" x 24 3/4"

36 3/4" x 32 3/4"

Casing Length & Width

32" x 20"

34" x 22"

34" x 30"

Overall Length Including Diverter

40"

43 1/2"

45 1/4"

Floor Opening, Length & Width

32 5/16" x 20 5/16"

34 5/16" x 22

5/16"

34 5/16" x 30

5/16"

Height

23"

26"

27"

Minimum Clearance to Combustibles

Top Must Be Open and Clear of ALL OBJECTS and Covering Each Side to:

Nearest Wall

6"

6"

6"

Bottom of Unit for Air

6"

6"

6"

Draft Diverter and Vent Connector

6"

6"

6"

Two Adjoining Sides to Walls to Provide a Walkway

18"

18"

18"

Gas Inlet

Iron pipe Size (N.P.T.)

1/2"

1/2"

1/2"

Inlet to Floor

18 1/2"

20 1/4"

20 1/4"

venting

Floor to Top of Diverter Shield

10 1/2"

12 3/4"

12 3/4"

Center of Flue (Horizontal) to Floor Covering

17 1/4"

18 3/4"

17 3/4"

Size of Flue Collar

4" Dia.

4" Dia.

5" Dia.

Introduction

Always consult your local Building Department regarding regulations,

codes or ordinances which apply to the installation of a floor furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after instal-

lation.

2. Installer must have owner fill out and mail warranty card sup

-

plied with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

Warning:

Any change to this furnace or its control can be dangerous.

this is a heating appliance and any panel, door or guard

removed for servicing an appliance must be replaced prior

to operating the appliance.

General Information

This series is design certified in accordance with American National

Standard Z21.86b-2002 by the Canadian Standards Association

as a gravity type Floor Furnace and must be installed according to

these instructions.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

Qualified Installing Agency

The installation must conform with local codes, in the absence of

local codes, with the National Fuel Gas Code ANSI Z2231*

*Available from the American National Standards Institute, Inc. 11 West 42nd St.,

New York, N.Y. 10018.

state of Massachusetts: the installation must be made by

a licensed plumber or gas fitter in the Commonwealth of

Massachusetts.

Important

All correspondence should refer to complete Model Number, Serial

Number and type of gas.

Notice:

During initial firing of this furnace, its paint will bake out and

smoke will occur. To prevent triggering of smoke alarms, ventilate

the room in which the furnace is installed.

to Conserve Gas: turn off pilot when heater is not in use.

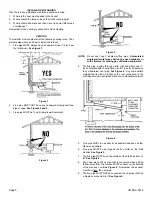

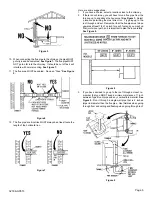

The flue pipe diameter must be as large as the flue collar on the

draft diverter and run as directly as possible to the chimney at least

1/4" rise per foot of run properly supported by metal straps, and enter

the chimney so the end of the flue pipe is flush with the inner wall

of the chimney. Any flue pipe passing through walls and roof must

be "B" type vent. The chimney must extend at least two feet above

the roof and any object or building within 10 feet of the chimney.

The flue pipe must NOT have any open tees or be connected to

the chimney of an existing fireplace.