5 – 12

Section 5 • Maintenance/Service

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

18. Remove shims and spherical washers from com-

pressor mounting locations.

19. Inspect shims and spherical washers for damage,

replace as required.

Installation

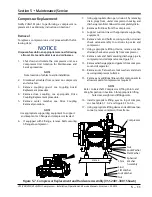

20. Install shims and spherical washers on compressor

mounting locations, see Figure 5-7.

21. Install appropriate lifting eyes on top of compres-

sor. See Table 3-1, 3-2, and Figure 3-1 to 3-6

NOTE

Refer to Bareshaft Compressor Lifting Points and

Weights portion in Section 3 for appropriate lifting

hole sizes, weights and lifting points.

22. Using appropriate lifting device, position compres-

sor on compressor mounting locations on frame.

23.

Loosely install studs, lock washers, flat washers and

nuts to secure compressor to frame until alignment

is correct.

24. Check compressor for soft foot. Add or remove

shims as required until measurements are within

+/- 0.002”.

25. Tighten nuts to secure compressor to frame, refer

to Appendix A.

26.

If equipped with C-flange, install bolts to se

-

cure C-flange to compressor. Tighten bolts, see

Appendix A.

27. Install drive coupling, see appropriate Drive

Coupling Replacement procedure.

28. Install center member, see Drive Center Member

Installation and Alignment procedure.

29. Install coupling guard, see Coupling Guard

Replacement procedure.

30. Install nuts and bolts to secure discharge pipe to oil

separator and compressor.

31. Tighten nuts on ‘discharge pipe-to-compressor

flange’ first, then tighten nuts on ‘discharge pipe-

to-oil separator flange’, see Appendix A.

32. Install nuts to secure suction strainer/check valve

assembly to compressor and suction stop valve.

33. Tighten nuts on ‘suction strainer/check valve as-

sembly-to-compressor’ first, then tighten nuts on

‘suction strainer/check valve assembly-to-suction

stop valve’, refer to Appendix A.

34. Install all lines to compressor.

35. Install all cables to sensors on compressor and

actuator.

36.

Perform leak check, see Compressor Unit Leak

Check procedure.

Содержание Vilter VSH

Страница 1: ...VSS VSR VSM VSH VSSH Installation Operation and Service Manual Single Screw Bare Shaft Compressor ...

Страница 2: ......

Страница 16: ...1 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 54: ...4 18 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 102: ...5 48 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 114: ...7 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 116: ...8 2 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 144: ...8 30 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 162: ...8 48 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 164: ...A 2 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 168: ...B 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 174: ...C 6 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 177: ......

Страница 179: ......

Страница 182: ......

Страница 183: ......

Страница 184: ......

Страница 200: ...E 12 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 204: ...F 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 205: ......