3 – 10

Section 3 • Installation

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

will avoid costly damage to the equipment due to

freezing.

This information is taken from ASHRAE 15-89 and ANSI/

ASME B31.5. The installing contractor should be thor-

oughly familiar with these codes, as well as any local

codes.

CAUTION

Accumulated liquid in the suction header can damage

the compressor if not drained. Always drain headers

(suction and discharge headers) prior to start-ups.

Failure to comply may result in damage to equipment.

Nozzle Dia. (in.)

Fz (lbf)

Fy (lbf)

Fx (ft-lbf)

Mzz (ft-lbf)

Myy (ft-lbf) Mxx (ft-lbf)

4

400

400

400

300

300

300

6

600

600

600

500

500

500

8

900

900

900

1000

1000

1000

10

1200

1200

1200

1200

1200

1200

12

1500

1500

1500

1500

1500

1500

14

2000

2000

2000

2000

2000

2000

Table 3-3. Maximum Allowable Flange Loads

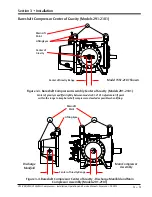

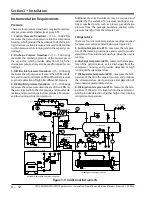

Figure 3-8. Maximum Allowable Flange Loads

DISCHARGE

LINE

5 PIPE

DIAMETERS

CUSTOMER

SUPPORT

3-4 PIPE

DIAMETERS

SUCTION

LINE

X

Z

Z

Y

X

Y

CUSTOMER

SUPPORT

DISCHARGE

LINE

5-6 PIPE

DIAMETERS

CUSTOMER

SUPPORT

3-4 PIPE

DIAMETERS

SUCTION

LINE

X

Z

Z

Y

X

Y

HANGER

CHECK

VALVE

HANGER

CHECK

VALVE

CUSTOMER SUPPORTS

WHEN CHECK VALVE

IS MOUNTED HERE

CUSTOMER SUPPORTS

WHEN CHECK VALVE

IS MOUNTED HERE

5 PIPE

DIAMETERS

5 PIPE

DIAMETERS

CHECK

VALVE

Flange Loads

The ideal load applied to flanges of the compressor unit

is zero. However, it’s not practical to expect that no loads

will be applied to unit connections. Thermal, dead, live,

wind & seismic loads must be considered and even toler-

ated. Well supported external piping connected to the

compressor will still result in some loads applying forces

and moments in three axes to unit flanges.

The most important issue is the motor-compressor mis-

alignment caused by external forces (F in lbf) and mo-

ments (M in ft-lbf) imposed by plant piping. In Figure

3-8 and Table 3-3, are the maximum allowable forces

and moments that can be applied to compressor flanges

when the compressor is mounted on an oil separator.

It must be noted that it is necessary to check for com-

pressor shaft movement when the job is complete. In

no case shall the attached piping be allowed to cause

more than 0.002” movement at the compressor shaft.

If more than 0.002” movement is detected the piping

Содержание Vilter VSH

Страница 1: ...VSS VSR VSM VSH VSSH Installation Operation and Service Manual Single Screw Bare Shaft Compressor ...

Страница 2: ......

Страница 16: ...1 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 54: ...4 18 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 102: ...5 48 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 114: ...7 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 116: ...8 2 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 144: ...8 30 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 162: ...8 48 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 164: ...A 2 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 168: ...B 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 174: ...C 6 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 177: ......

Страница 179: ......

Страница 182: ......

Страница 183: ......

Страница 184: ......

Страница 200: ...E 12 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 204: ...F 4 Blank VSS VSR VSM VSH VSSH Compressor Installation Operation and Service Manual Emerson 35391S ...

Страница 205: ......