August 2020

Reference Manual

L231040 Rev AD

19

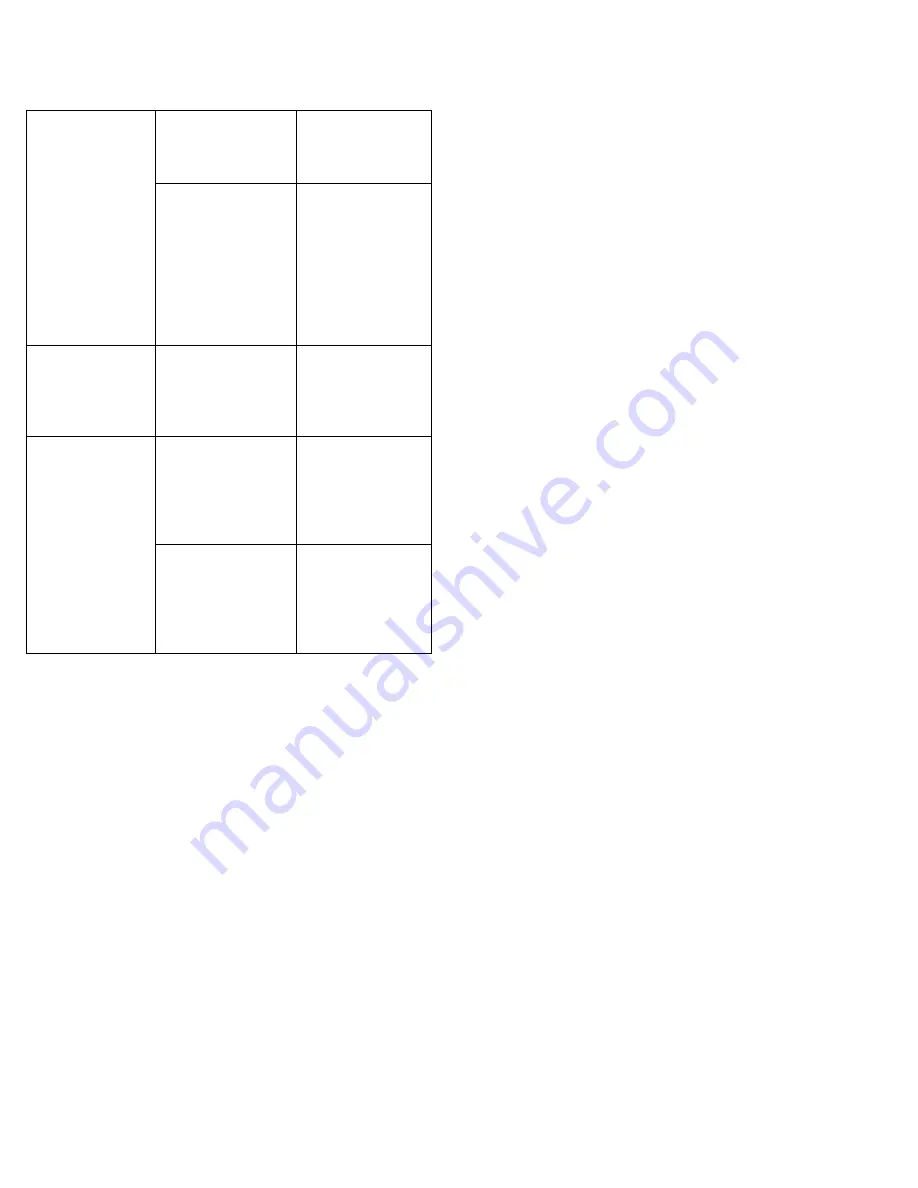

Local display

showing dark

black squares or

blinking "please

standby"

LCD did not initialize

properly

Cycle power rapidly

(this may have to

be done a few

times).

Electronics module

failure

Replace electronics

with known

working electronics

from a sensor of

similar length

and/or contact

factory for

replacement

assistance.

Cannot enter into

menus local

display menus

using push

buttons

Write protect jumper

is locking buttons

Move the blue

jumper from the

right

(2pins) to the left

(2pins).

Transmitter output

does not match

display

If the mA output

greater than

22mA then

Electronics module

failure (most likely

due to power surge)

Consult factory for

replacement

assistance

(non-warranty)

If the mA output less

than 22mA

but slightly different

from

display then DAC

Trim

Perform DAC trim

described in section

7.1.

6.3 Changing Signal Parameters

There are 3 parameters involved with “Energy Settings”.

These parameters are Energy, DCOffset and HoldTime.

•

Energy [%] is the amount of energy (a voltage

correlated to percentage) being sent down the

sensor probe.

•

DCOffet [V] is the DC voltage that the signal is

offset by. It is useful for eliminating some noise.

•

HoldTime [µs] is how long the Energy is sent down

for.

Symptom: Transmitter is erratic (i.e. output going

from correct reading to failure mode).

Possible Resolution:

Increase Energy Settings:

1. Unlock the pushbuttons by moving the blue jumper

to the left, Hold the UP button for 1sec

2. While holding the UP button also hold ENTER

button (together) for 3 secs

3. The menu should change to “ComPort” release the

buttons

4. Bypass this menu by pressing enter.

5. Keep bypassing the menus until you see “ChgSgnl”,

6. Use the up or down arrows to change the “no” to a

“yes” and press enter.

7. The next Menu will say “Energy” and a

percentage, increase this number by 10 [%] and

press enter. (i.e. 20 to 30 %)

8. The next Menu will say “DCOffset”, and a voltage,

leave this value unchanged and press Enter.

9. The next menu will say “HoldTime” and a number;

increase this number by 2 [µs] and press enter.

(i.e. 4 to 6 µs)

10. Then simply press enter until you see the “Exit”

menu and then press enter one last time.

The above procedure can also help if the output is in

constant failure mode. If the procedure does not help

please contact factory for further assistance. 1-800-221-

3653.

Section 7: LTM-350 has HART Protocol

7.0 Hart Protocol: General Information

The LTM-350 is a HART registered and certified instrument.

The section presents how the HART Communication

Protocol has been utilized in the LTM-350. This section

does not explain what HART Protocol is, please visit

www.hartcomm2.org to learn about HART.