7

50 (3.45)

1 (1.4)

1 (1.4)

2 (2.7)

2 (2.7)

100 (6.89)

2 (2.7)

3 (4.1)

4 (5.4)

4 (5.4)

150 (10.34)

2 (2.7)

4 (5.4)

5 (6.8)

6 (8.1)

200 (13.79)

3 (4.1)

5 (6.8)

7 (9.5)

8 (10.8)

250 (17.24)

4 (5.4)

6 (8.1)

9 (12.2)

10 (13.6)

300 (20.68)

5 (6.8)

7 (9.5)

11 (14.9)

12 (16.3)

Hydrostatic test using gag

The safety valve test gag shown in Figure 5 can

be used with both welded and flanged inlets,

but at pressures no greater than 10% above the

nameplate set pressure.

Gagging should be done very carefully in

order not to overload the valve spindle or

cause damage to the valve seats.

The following outlines the recommended

procedure for gagging valves for

hydrostatic test:

• Remove the lever (27), forked lever (30),

cap (25) and spindle nut (23).

• Refer to Figure 5. Lubricate the threads and

pointed end of the gag screw. Install the

gag in place, being careful that the legs fit

uniformly. Contacts on both legs of the gag

should seat evenly on the underside of the

bonnet top.

• Tighten the gag finger-tight only at this point.

• Raise the system pressure to approximately

100 psig below the nameplate set pressure

of the safety valve.

• Apply the necessary torque to the gag in

accordance with the value shown in the

table above for the specific orifice size. This

torque value is determined as follows:

- Determine Δ by subtracting the valve set

pressure from the hydrostatic test pressure.

- Read the value of Δ on the vertical scale.

Proceed horizontally to the appropriate

orifice size and then down to read the

torque on the horizontal scale.

- The torque values (foot-pounds) obtained

should be increased by a factor of

approximately 25% to account for normal

variations in friction, safety valves and

test conditions.

CAUTION

Gags should not be used when inlet pressures are

more than 10% greater than the safety valve set

pressure. Damage to the valve may result.

CAUTION

Should any safety valve show seat leakage, the

pressure must be lowered until the leakage stops.

CAUTION

Never increase the gagging load while a safety

valve shows seat leakage. This can result

in damage to the valve seats and bending

of the spindle.

CAUTION

Valve gags should not be left on the valves in

a gagged or loaded position for an extended

period or under conditions where large thermal

variations are expected.

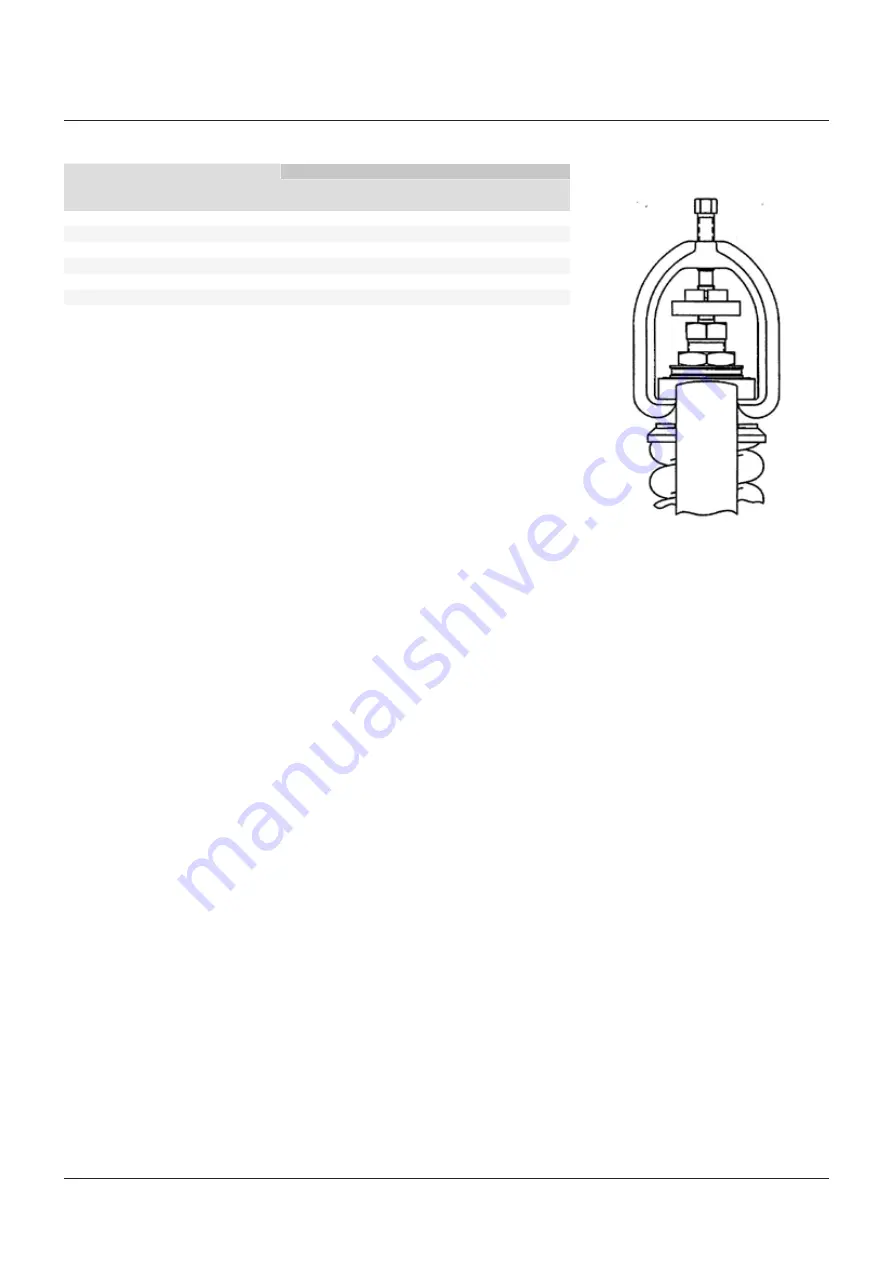

FIGURE 5 - VALVE GAG

POSITION GAG EVENLY ON BONNET

• The torque should then be increased on the

gag about 10% above the initial torque value.

• After the hydrostatic test, the pressure on the

system should be dropped to approximately

100 psi below the nameplate set pressure of

the safety valve. The gags should be loosened

at this point and removed from the valves.

• After the hydrostatic test, the gag should be

removed and the cap reinstalled according

to Section 10 - paragraph 'Assembly of cap'.

NORMAL GAGGING LOAD in ft·lb OF TORQUE (Nm) VS. ΔP

ΔP

Orifice

(Overpressure less valve set pressure)

psi (bar)

psi (bar)

K

K

2

M

M

2

CROSBY

®

STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

• After applying the necessary torque to the

gags, increase the hydrostatic test pressure

to the required amount. Observations should

be made during the rising pressure cycle to

determine if any of the safety valves show

seat leakage.