C6.3.2/0416-0716/E

19

NOTE: For more information please refer to Technical Information D7.8.4 "CoreSense

™

Diagnostics for Stream refrigeration compressors".

4.6 CoreSense

™ Protection

4.6.1 Motor protection

Stream Digital compressors with "-P" at the end of the description are equipped with a

CoreSense Protection device. The temperature-dependent resistance of the thermistor (also

PTC-resistance) is used to sense the winding temperature. Two chains of three thermistors each

connected in series are embedded in the motor windings in such a manner that the temperature

of the thermistors can follow with little inertia.

The CoreSense Protection module switches a control relay depending on the thermistor

resistance. It is installed in the terminal box to which the thermistors are connected.

NOTE: The maximum test voltage for thermistors is 3V.

The total resistance of the thermistor chains on a cold compressor should be ≤ 1800Ω.

Protection class of the module: IP20.

IMPORTANT

Different sources for power supply and contact 11-14! Module

malfunction!

Use the same potential for the power supply (L) and the switch

contact of the control loop (11-14).

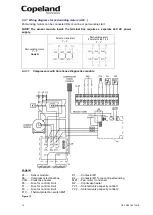

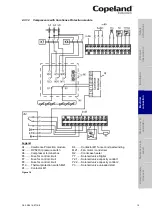

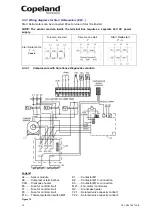

Control circuit wiring:

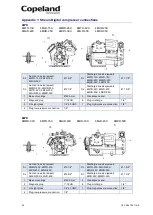

Figure 19: Control circuit wiring diagram

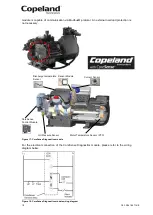

4.6.2 Oil pressure control

The oil pressure switch breaks the control circuit when the pressure difference between the oil

pump outlet and the crankcase is too low. The switch must be properly adjusted and tamper-

proof. If the oil differential pressure drops below the minimum acceptable value the compressor

will stop after a 120-second delay. After having solved the problem the control has to be reset

manually.

NOTE: Proper oil pressure safety control with an approved switch is a condition of

warranty!

The following oil pressure switches can be delivered as accessories:

Electronic oil pressure switch OPS2

Mechanical oil pressure switch Alco Control FD-113ZU

4.6.2.1

Electronic oil pressure switch

– OPS2

The specifications for the OPS2 oil pressure switch are as follows:

Differential pressure: 0.95 ± 0.15 bar

Time delay:

120 ± 15 sec.

S

afet

y

in

struct

ion

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

Dismant

ling

&

d

ispo

sa

l