1592006207 XB570L GB r1.1 23.03.2015 XB570L

2/20

3. GENERAL FEATURES

The series XB has been created for fast chilling or freezing goods according to international food safety

standards.

There are FOUR types of cycles:

•

The CYCLES: Cy1, Cy2, Cy3, Cy4 are pre-set according to the most common cycles used in food -

safety applications; the user can select one of them according to his own requirements and modify it as

he wants.

•

Any cycle can be manually terminated before the normal.

•

Any cycle can use the insert probes (up to 3), they measures the internal temperature of the product.

•

During the Cycle there are no defrosts and the fans are always on, a defrost cycle can be done before

any freezing cycle.

•

The cycle is divided up to 3 phases completely configurable by the user.

•

Each instrument is provided with an output for remote display XR REP, which shows the temperature of

cabinets or goods.

•

The XB570L controller is provided with internal real time clock and can be connected to the XB07PR

printer. This means that a report, which includes all the main features of cycle, can be printed: start and

end of the cycle, length of the cycle, logging of the temperature of the cabinet and goods.

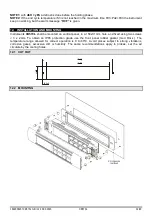

4. MOUNTING & INSTALLATION

Model XB570L is a controller for panel mounting: the cut out dimensions are 150x31 mm and it has to be

fixed with screws. The ambient operating temperature range is from 0.0 to 60°C. Avoid locations subject to

heavy vibration, corrosive gases or excessive dirt. The same warnings have to be applied to the probes.

Ensure enought ventilation around the instrument.

5. ELECTRICAL CONNECTIONS

The instruments are provided with a screw terminal block to connect cables with a cross section up to

2.5mm

2

for probes and digital input.

Spade on 6.3 mm heat-resistant wiring for supply and loads. Before connecting cables make sure the power

supply complies with the instrument’s requirements. Separate the input connection cables from the power

supply cables, from the outputs and the power connections.

Do not exceed the maximum current allowed

on each relay

, in case of heavier loads, a suitable external relay has to be used.

5.1 PROBES CONNECTION

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid infiltration. It is

recommended to place the thermostat probe away from air streams to correctly measure the average room

temperature. Place the defrost termination probe among the evaporator fins in the coldest place, where

most ice is formed, far from heaters and from the warmest place during defrost, to prevent premature

defrost termination.

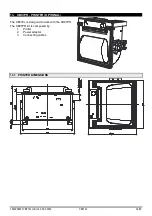

6. CONNECTIONS

R

oo

m

In

se

rt

1

11

9 10

12 13

17 18 19

21

14

PRINTER

Co

nf.

In

p.

Co

mm

on

Do

or

Supply

115V

~

N

Light

Comp

MAX

20A

16A

250V

~

6 7 8

5

Def

Fan

8A

250V

~

8A

250V

~

De

f

20

3

2

1

4

Alarm

16A

250V

~

8A

250V

~

Remote

Display

25 26 27 28 29 30 31

RS 485

Line

20A 250V

16FLA(96LRA)

In

se

rt

2

In

se

rt

3

HO

T

KE

Y

oA2

oA3

oA1